When a driver presses the brake pedal expecting immediate response—whether stopping at a traffic light, avoiding a collision, or descending a mountain grade—the difference between safe deceleration and catastrophic failure often depends on automotive pressure switches for clutches and brakes detecting hydraulic pressure loss before complete brake failure occurs. With modern vehicles equipped with advanced braking systems including ABS, ESC (Electronic Stability Control), and regenerative braking in EVs/hybrids, pressure monitoring has evolved from simple warning lights to sophisticated safety systems preventing thousands of accidents annually. Yet automotive manufacturers and aftermarket suppliers face increasing challenges: stricter safety regulations, extreme operating conditions (-40°F to 300°F), vibration resistance requirements (20g+), and 150,000+ mile service life expectations across conventional, hybrid, and electric vehicle platforms.

🚗 Understanding Hydraulic Pressure Monitoring in Automotive Systems

Why Pressure Switches Are Critical for Vehicle Safety

Automotive pressure switches for clutches and brakes serve as the first line of defense against hydraulic system failures that could cause accidents, injuries, or fatalities:

Primary Safety Functions

- 🔴 Brake Fluid Level/Pressure Warning: Alerts driver to low brake fluid (leak detection) before pedal travel reaches floor

- 🔴 Dual-Circuit Monitoring: Detects front/rear circuit failure in split braking systems (federal safety requirement)

- 🔴 Parking Brake Release Verification: Confirms hydraulic parking brake disengaged before driving

- 🔴 ABS Hydraulic Accumulator Pressure: Monitors accumulator pre-charge ensuring ABS system readiness

- 🔴 Clutch Hydraulic Pressure: Prevents clutch slip from insufficient hydraulic pressure (manual transmissions)

- 🔴 Automated Manual Transmission (AMT): Verifies clutch actuation pressure for gear shift execution

Regulatory and Safety Standards

Automotive brake systems must comply with stringent regulations:

| Standard/Regulation | Requirement | Pressure Switch Role |

|---|---|---|

| FMVSS 135 (US) | Dual-circuit brake systems with warning indicator | Detects hydraulic pressure differential >150 PSI between circuits |

| ECE R13 (Europe) | Brake fluid level warning, pressure monitoring | Activates warning when fluid drops or pressure fails |

| ISO 26262 | Functional safety (ASIL B/C for braking systems) | Pressure switches must meet failure rate specifications |

| SAE J1850 | Vehicle network communication standards | Digital pressure switches communicate via CAN bus |

| AIS-052 (India) | Brake system requirements and testing | Pressure monitoring for commercial vehicles >3.5 tons |

⚖️ Legal Liability: Brake system failures causing accidents expose manufacturers to product liability claims. Properly specified and tested automotive pressure switches for clutches and brakes provide documented safety systems reducing liability exposure.

🛑 Brake System Pressure Switch Applications

Master Cylinder Pressure Monitoring

Dual-Circuit Brake Warning Switches

Modern vehicles use split braking systems (diagonal, front/rear, or X-split configurations) where master cylinder contains two independent hydraulic circuits. Pressure differential switches detect circuit failure:

Operating Principle:

- Switch contains two pressure chambers separated by piston/shuttle

- Under normal operation, both circuits maintain equal pressure—piston centered, switch open

- If one circuit fails (leak, seal failure), pressure differential moves piston, closing electrical contact

- Warning light illuminates alerting driver to partial brake system failure

- Remaining circuit provides 50-60% braking capability (emergency stopping)

Technical Specifications:

- Activation Pressure Differential: 100-200 PSI typical (OEM-specified based on system design)

- Operating Pressure Range: 0-2,000 PSI (brake system normal operating pressure 800-1,200 PSI)

- Electrical Rating: 12V/24V automotive systems, 0.5-2 amp switching capacity

- Temperature Range: -40°F to +300°F (engine compartment + brake heat)

- Vibration Resistance: 20g continuous, 50g shock (automotive standard)

- Service Life: 150,000+ miles / 10+ years

Brake Pedal Position/Pressure Sensing

Modern vehicles integrate pressure sensors measuring driver brake pedal force for:

- Brake-by-Wire Systems: Electronic brake actuation replacing direct hydraulic connection

- Regenerative Braking Blending: Coordinates friction brakes with electric motor regeneration (EVs/hybrids)

- Advanced Driver Assistance (ADAS): Automatic emergency braking, adaptive cruise control

- Brake Assist Systems: Detects emergency braking (rapid pedal application) and maximizes brake pressure

Sensor Requirements:

- Output Type: Analog voltage (0-5V ratiometric), CAN bus digital signal

- Accuracy: ±2-5% full scale (proportional control requires higher accuracy than switches)

- Response Time: <10 ms (emergency braking systems demand fast response)

- Redundancy: Dual sensors for safety-critical systems (ISO 26262 ASIL C/D)

Anti-Lock Braking System (ABS) Pressure Monitoring

Hydraulic Accumulator Pressure Switches

ABS systems use hydraulic accumulators storing pressurized brake fluid (1,500-2,500 PSI) enabling rapid pressure modulation during wheel lock-up events:

Pressure Switch Functions:

- Accumulator Pre-Charge Monitoring: Verifies accumulator pressure adequate before ABS operation

- Pump Control: Activates hydraulic pump when accumulator pressure drops below minimum threshold

- System Ready Indicator: ABS warning light extinguishes only when sufficient accumulator pressure available

- Fault Detection: Identifies accumulator nitrogen pre-charge loss or pump failure

Typical Pressure Ranges:

- Pump Start Pressure: 1,800-2,000 PSI (activates pump to recharge accumulator)

- Pump Stop Pressure: 2,400-2,600 PSI (pump cuts off at maximum pressure)

- Low Pressure Warning: <1,500 PSI (ABS may not function properly)

Electronic Stability Control (ESC) Systems

ESC systems extend ABS functionality, applying individual wheel braking to correct vehicle understeer/oversteer:

- Higher Pressure Requirements: ESC actuators generate up to 2,000 PSI independent of driver input

- Faster Response: Pressure switches with <5 ms response time

- Continuous Monitoring: Real-time pressure verification during ESC intervention

- Diagnostic Capability: Pressure switch faults logged in vehicle diagnostic system (OBD-II)

🔧 Clutch System Pressure Switch Applications

Hydraulic Clutch Release Systems

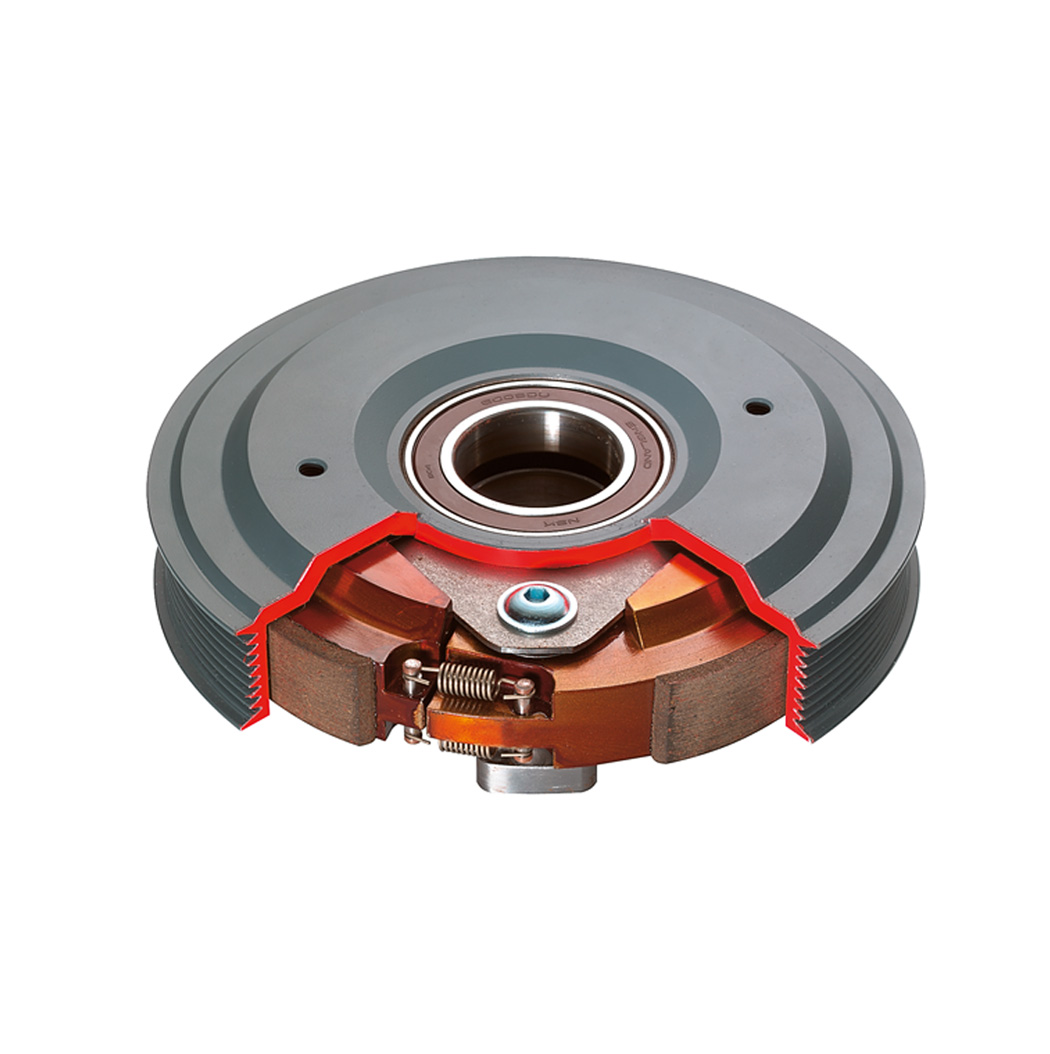

Manual Transmission Clutch Monitoring

Hydraulic clutch actuation systems (replacing mechanical cables in modern vehicles) use pressure switches for:

Primary Functions:

- Clutch Pedal Position Sensing: Determines clutch engagement state for engine start interlock (must depress clutch to start engine—safety requirement)

- Hydraulic Pressure Verification: Confirms adequate pressure for complete clutch disengagement

- Leak Detection: Low pressure warning indicating hydraulic leak or slave cylinder failure

- Clutch Drag Prevention: Ensures clutch fully releases preventing gear grinding and synchronizer wear

Operating Pressure Ranges:

- Light Duty (Passenger Cars): 200-600 PSI operating pressure

- Medium Duty (Light Trucks): 600-1,200 PSI

- Heavy Duty (Commercial Trucks): 1,000-2,000 PSI (dual-plate clutches, high clamping force)

Automated Manual Transmissions (AMT) and Dual-Clutch Transmissions (DCT)

Electro-Hydraulic Clutch Actuation

AMT and DCT systems eliminate clutch pedal, using computer-controlled hydraulic actuation:

Pressure Switch/Sensor Roles:

- Clutch Position Feedback: High-accuracy pressure sensors (±1% FS) provide clutch engagement point control

- Hydraulic Pressure Regulation: Closed-loop control maintaining precise clutch slip during launches and shifts

- Thermal Protection: Monitors clutch pressure during extended slip (traffic, hill starts) preventing overheating

- Shift Quality Optimization: Pressure profiling creates smooth, fast shifts (DCT shift times <100 ms)

- Safety Interlocks: Prevents transmission engagement with insufficient clutch pressure

Advanced Requirements:

| Parameter | Basic AMT | Performance DCT | Reason |

|---|---|---|---|

| Accuracy | ±2-5% FS | ±0.5-1% FS | Precise clutch slip control for smoothness |

| Response Time | <20 ms | <5 ms | Fast shifts require rapid pressure monitoring |

| Temperature Range | -40°F to +250°F | -40°F to +300°F | Performance driving generates higher heat |

| Cycle Life | 500,000+ cycles | 1,000,000+ cycles | DCT shifts every 2-3 seconds in traffic |

| Output Type | Analog voltage | CAN bus digital | Integration with transmission control module |

Heavy-Duty Commercial Vehicle Applications

Air-Over-Hydraulic Brake and Clutch Systems

Commercial trucks, buses, and construction equipment often use air-over-hydraulic systems combining pneumatic and hydraulic actuation:

Pressure Switch Applications:

- Air Pressure Monitoring: 90-120 PSI air system pressure (activates warning if compressor fails)

- Hydraulic Pressure Multiplication: Verifies hydraulic pressure proportional to air input (air-to-hydraulic booster operation)

- Spring-Applied Hydraulic-Release Parking Brakes: Monitors hydraulic pressure holding parking brake released

- Multi-Axle Coordination: Pressure switches on each axle verify brake application

- Trailer Brake Pressure: Monitors tractor-to-trailer brake pressure supply (prevents trailer separation)

🔌 Electrical and Mechanical Specifications

Switch Contact Ratings

Proper electrical specification prevents premature contact failure:

Contact Load Considerations

| Load Type | Typical Current | Switch Rating Required | Application |

|---|---|---|---|

| LED Warning Light | 20-50 mA | 0.5 A minimum (low-level switching) | Modern dashboard indicators |

| Incandescent Bulb | 0.5-2 A | 2-3 A continuous rating | Older vehicles, high-current indicators |

| Relay Coil | 100-200 mA | 0.5-1 A (inductive load suppression required) | Activating warning systems, pumps |

| Solenoid Valve | 0.5-1.5 A | 2-3 A with inrush tolerance | ABS hydraulic valves |

| ECU Digital Input | <10 mA | Low-level switching (gold contacts) | CAN bus interfaced systems |

⚠️ Common Mistake: Using low-current switches (designed for ECU inputs) to drive LED warning lights causes contact oxidation and failure. Specify switches rated for actual load plus 50% safety margin.

Environmental and Mechanical Requirements

Vibration and Shock Resistance

Automotive environments subject components to severe mechanical stress:

- Continuous Vibration: 10-2000 Hz at 10-20g acceleration (engine, road, suspension inputs)

- Shock Events: 50-100g pulses from potholes, railroad crossings, off-road use

- Testing Standards: SAE J1455 (electrical connector vibration), MIL-STD-810 (military vehicle environments)

- Design Solutions: Welded construction eliminates internal threaded parts that loosen, Silicon-on-Sapphire sensing elements provide superior mechanical strength (9 Mohs hardness)

Temperature Extremes

Automotive pressure switches must function across wide temperature ranges:

- Ambient Extremes: -40°F (Alaska winters, cold starts) to +125°F (desert summer, under-hood)

- Brake System Heat: Brake components reach 300-500°F during heavy braking (mountain descents, track use)

- Heat Soak: After engine shutoff, under-hood temperatures climb 50-100°F above operating temperature

- Thermal Cycling: Switches experience thousands of -40°F to +300°F cycles over vehicle lifetime

- Solution: Automotive-rated switches specify -40°F to +300°F operating range with appropriate seal materials (Viton, EPDM) and temperature-stable sensing technology

Fluid Compatibility

| Fluid Type | Compatible Seal Materials | Incompatible Materials | Applications |

|---|---|---|---|

| DOT 3/DOT 4 Brake Fluid | EPDM, SBR, Silicone | Natural rubber (swells), NBR | Most passenger vehicle brakes |

| DOT 5 (Silicone) | Silicone, Viton | EPDM (not compatible) | Military vehicles, motorcycles |

| DOT 5.1 (Low Viscosity) | EPDM, SBR | Natural rubber, NBR | ABS/ESC systems requiring low-viscosity fluid |

| Mineral Oil Hydraulics | NBR (Buna-N), Viton | EPDM (swells in petroleum) | Clutch hydraulics, some European brakes |

💡 Critical Consideration: Brake fluid compatibility is non-negotiable. Wrong seal material causes swelling, degradation, and dangerous brake fluid leaks. Always verify fluid type before specifying pressure switches.

🚙 Electric Vehicle (EV) Brake System Innovations

Regenerative Braking Integration

EVs and hybrids recover kinetic energy during braking, converting it to electricity recharging batteries. This creates unique pressure monitoring requirements:

Brake Blending Systems

How It Works:

- Driver presses brake pedal requesting deceleration

- Vehicle computer determines regenerative braking capacity (limited by battery charge state, motor speed)

- Hydraulic brake pressure fills remaining deceleration requirement

- Seamless blending creates consistent pedal feel while maximizing energy recovery

Pressure Switch/Sensor Requirements:

- High Accuracy: ±1% or better for smooth regenerative-to-friction transition

- Fast Response: <10 ms to coordinate electric motor and hydraulic brake timing

- Redundant Sensors: Dual pressure sensors for safety (if one fails, hydraulic brakes provide full stopping power)

- CAN Bus Communication: Digital integration with battery management system, motor controller, brake control module

Brake-by-Wire Systems

Advanced EVs eliminate direct hydraulic connection between brake pedal and wheel brakes:

System Architecture:

- Pedal Simulator: Provides realistic brake pedal feel through hydraulic resistance (no mechanical connection to brakes)

- Pressure Sensors: Measure driver input force/displacement

- Electronic Control Unit: Calculates required brake torque, commands electro-hydraulic actuators

- Wheel Brake Actuators: Individual hydraulic units at each wheel with integrated pressure sensors

- Redundant Architecture: Backup mechanical connection for electronic system failure

Advantages:

- Optimized regenerative braking (up to 70% city driving energy recovery)

- Individual wheel brake control (enhanced ESC, torque vectoring)

- Automated emergency braking integration

- Reduced weight (shorter hydraulic lines, fewer components)

- Customizable brake feel (sport, comfort, efficiency modes)

One-Pedal Driving Systems

Many EVs implement “one-pedal driving” where lifting accelerator pedal provides strong regenerative braking deceleration approaching full stops:

- Blended Deceleration: Regenerative + friction brakes coordinate seamlessly

- Pressure Monitoring: Detects when hydraulic brakes activate during regenerative deceleration

- Brake Light Activation: Pressure switches trigger brake lights during regenerative braking (safety requirement)

- Hill Hold Function: Hydraulic pressure maintains vehicle stationary on inclines after one-pedal stop

🔍 Selection Criteria for Automotive Pressure Switches

Application-Specific Selection Guide

Brake Warning Switches (Passenger Vehicles)

Requirements:

- Pressure differential activation: 100-200 PSI

- Operating pressure range: 0-2,000 PSI

- Electrical: 12V, 0.5-2A switching capacity

- Temperature: -40°F to +300°F

- Vibration: 20g continuous, 50g shock

- Seal material: EPDM (DOT 3/DOT 4 brake fluid)

- Service life: 150,000+ miles minimum

Recommended: SUCO ESI automotive-rated pressure switches with proven 200,000+ mile field performance

ABS Accumulator Pressure Switches

Requirements:

- Dual setpoints: Low pressure (1,800 PSI), high pressure (2,600 PSI)

- High-pressure capability: 0-3,000 PSI minimum

- Accurate setpoint tolerance: ±50 PSI (prevents pump short-cycling)

- Fast response: <10 ms for pump control

- High cycle life: 100,000+ actuations (pump cycles)

Heavy-Duty Commercial Vehicle Brakes

Requirements:

- Higher pressure: 0-3,000 PSI operating range

- Rugged construction: Welded stainless steel body

- 24V electrical system compatibility

- IP67 environmental protection (washdown, road spray)

- Trailer disconnect detection: Monitors trailer brake line pressure

- Extended service intervals: 500,000+ miles

Common Selection Mistakes to Avoid

- ❌ Insufficient Pressure Rating: Using 1,000 PSI switch in 2,000 PSI brake system—premature failure

- ❌ Wrong Seal Material: NBR seals in DOT 3 brake fluid—swelling and leaks within months

- ❌ Inadequate Temperature Rating: +200°F max temp switch near brake calipers—fails during mountain driving

- ❌ Low Contact Rating: Milliamp-rated switch driving incandescent bulb—contact oxidation, intermittent operation

- ❌ Poor Vibration Resistance: Industrial-grade switch in automotive environment—threaded components loosen, internal failures

🔧 Installation and Maintenance Best Practices

Proper Installation Procedures

Brake and Clutch System Installation

- System Depressurization: Release all hydraulic pressure before switch installation/removal

- Thread Sealant: Use brake-fluid-compatible thread sealant or PTFE tape (do NOT use standard pipe dope—contaminates fluid)

- Torque Specifications: Follow OEM torque specs (typically 10-20 ft-lbs for 1/8″-1/4″ NPT connections)

- Bleed Air: After installation, bleed brake system removing trapped air (critical for proper operation)

- Electrical Connections: Use OEM-quality connectors with proper seal, strain relief

- Wire Routing: Secure wiring away from hot exhaust components, sharp edges, rotating parts

Troubleshooting Common Issues

Brake Warning Light Always On

Diagnostic Steps:

- Check brake fluid level—low fluid activates warning

- Inspect for hydraulic leaks (brake lines, calipers, master cylinder)

- Test parking brake release—parking brake switch may be stuck

- Verify pressure switch electrical connection—corrosion, loose terminal

- Test switch continuity—should be open with equal pressure both circuits

Brake Warning Light Never Illuminates (Even with Parking Brake)

Diagnostic Steps:

- Check warning light bulb/LED—burned out bulb most common cause

- Verify power to warning light circuit—use multimeter

- Test switch operation—apply vacuum to one port, should close contact

- Inspect wiring—broken wire, blown fuse

- Check ground connection—poor ground prevents light operation

📈 Market Trends and Future Outlook

Growing Market Opportunities

The automotive pressure switch market is experiencing strong growth driven by multiple factors:

Electric Vehicle Adoption

- Market Growth: EV sales projected to reach 30-40% of new vehicle sales by 2030 (IEA forecast)

- Increased Sensor Content: EVs require 2-3x more pressure sensors than conventional vehicles (battery cooling, brake blending, thermal management)

- Higher Performance Requirements: Regenerative braking demands ±1% accuracy vs. ±5% for conventional systems

- Opportunity: $2-5 billion addressable market for EV pressure sensing by 2030

Advanced Safety Systems

- Regulation-Driven Growth: Automatic emergency braking (AEB) becoming mandatory globally

- Level 2+ ADAS: Advanced driver assistance systems standard on new vehicles

- Redundant Sensing: Safety-critical systems require dual pressure sensors (ISO 26262)

- Opportunity: Premium pressure sensors with digital communication, diagnostics, redundancy

Commercial Vehicle Electrification

- Electric Trucks/Buses: Heavy-duty vehicle electrification accelerating (city buses, delivery trucks)

- Pneumatic-to-Hydraulic Transition: Electric trucks replacing air brakes with electric-hydraulic systems

- Regenerative Braking: Heavy vehicles recovering substantial energy during frequent stops

- Opportunity: High-pressure, high-accuracy sensors for heavy-duty EV braking

🌟 SUCO ESI Automotive Pressure Switch Solutions

SUCO ESI has supplied the automotive industry for over 40 years with pressure switches proven in millions of vehicles worldwide:

Automotive Product Portfolio

- ✅ Brake Pressure Switches: Dual-circuit warning, ABS accumulator, master cylinder monitoring

- ✅ Clutch Pressure Switches: Hydraulic clutch actuation, AMT/DCT control, leak detection

- ✅ High-Accuracy Transducers: ±0.5-1% accuracy for EV brake blending, SoS technology for long-term stability

- ✅ Digital Communication: CAN bus, LIN bus outputs for modern vehicle networks

- ✅ Custom Solutions: Application-specific designs for OEM requirements

- ✅ Global Manufacturing: North American production with automotive quality systems

Quality and Certification

- Automotive Standards: ISO/TS 16949 quality management (predecessor to IATF 16949)

- Environmental Testing: Vibration, temperature cycling, salt spray per automotive specs

- Long-Term Reliability: 150,000+ mile proven performance in field applications

- PPAP Documentation: Production Part Approval Process support for OEM suppliers

Contact SUCO ESI for Automotive Solutions

📞 Phone: 1-800-473-7313

🌐 Website: www.sucoesi.com

📧 Contact: Request Automotive Product Information

Related Resources:

- Complete Guide to Electrical Pressure Sensors

- Download Automotive Pressure Switch Datasheets

- Pressure Sensor Troubleshooting Guide

Automotive pressure switches for clutches and brakes ensure critical safety system operation protecting drivers, passengers, and other road users. SUCO ESI combines decades of automotive experience with advanced pressure sensing technology delivering reliable, long-life solutions for conventional, hybrid, and electric vehicles. 🚗

Automotive Pressure Switches for Clutches and Brakes