Walk into virtually any industrial facility worldwide—from Texas oil refineries to German chemical plants, Australian mining operations to Japanese automotive factories—and you’ll find thousands of 4-20mA pressure transmitters reliably communicating measurement data across distances exceeding 1,000 meters through simple two-wire connections, immune to electrical noise that would render voltage signals useless. Yet despite ubiquity spanning seven decades since Honeywell introduced the current loop standard in the 1950s, engineers still struggle with loop power calculations, troubleshoot incorrect wiring causing sensor failures, and miss opportunities to leverage HART (Highway Addressable Remote Transducer) protocol superimposing digital communication onto analog 4-20mA signals.

⚡ Understanding 4-20mA Current Loop Fundamentals

What is a 4-20mA Signal?

A 4-20mA pressure transmitter outputs electrical current proportional to measured pressure, with 4 milliamps representing the lower range value (LRV) and 20 milliamps representing the upper range value (URV):

Signal Relationship

- 0% of range (LRV) = 4.00 mA

- 25% of range = 8.00 mA

- 50% of range = 12.00 mA

- 75% of range = 16.00 mA

- 100% of range (URV) = 20.00 mA

📐 Calculation Formula:

Current (mA) = 4 + [(Pressure - LRV) / (URV - LRV)] × 16

Example: 0-1000 PSI transmitter measuring 750 PSI:

Current = 4 + [(750 - 0) / (1000 - 0)] × 16 = 4 + (0.75 × 16) = 4 + 12 = 16.00 mA

Why 4-20mA Instead of 0-20mA?

The 4 mA “live zero” provides critical diagnostic capabilities:

- ✅ Broken Wire Detection: 0 mA indicates broken wire/failed power vs. legitimate zero pressure (4 mA)

- ✅ Sensor Power: Minimum 4 mA current provides power for transmitter electronics at zero pressure

- ✅ Alarm Capability: Current <3.5 mA or >21 mA signals fault condition (underrange/overrange)

- ✅ Cable Resistance Compensation: Constant current flow simplifies voltage drop calculations

⚠️ Fault Signaling Standards:

- 3.6-3.8 mA: Sensor fault or configuration error

- 0 mA: Broken wire, no power, or failed transmitter

- 20.5-22 mA: Overrange condition (pressure exceeds URV)

- >22 mA: Sensor saturated or electronics failure

🔌 4-20mA Loop Power and Wiring

Two-Wire Loop-Powered Configuration

Most 4-20mA pressure transmitters use elegant two-wire design where same wires carry both power and signal:

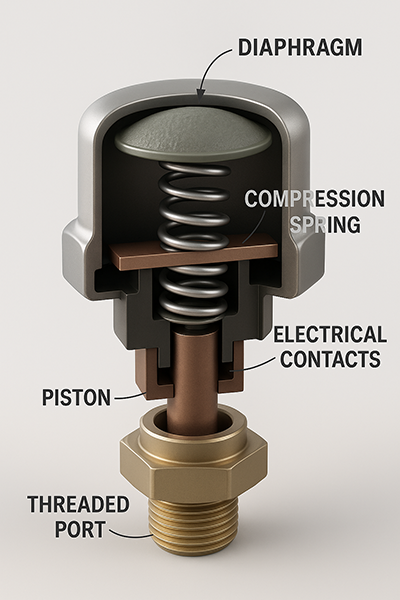

Basic Loop Components

- Power Supply: Typically 24 VDC (range 12-42 VDC depending on transmitter)

- Pressure Transmitter: Regulates current draw proportional to pressure

- Load Resistor: Converts current to voltage for measurement (typically 250Ω)

- Wiring: Two-conductor cable connecting components in series

How Loop Powering Works

- Power supply provides voltage (e.g., 24 VDC)

- Transmitter regulates current based on measured pressure (4-20 mA)

- Current flows through load resistor creating voltage drop: V = I × R

- PLC/DCS measures voltage across resistor, calculates current, determines pressure

Example: 250Ω load resistor

- 4 mA: V = 0.004 × 250 = 1.00 VDC (0% pressure)

- 12 mA: V = 0.012 × 250 = 3.00 VDC (50% pressure)

- 20 mA: V = 0.020 × 250 = 5.00 VDC (100% pressure)

Loop Power Supply Voltage Calculation

Ensuring adequate voltage prevents “loop drooping” errors:

Required Voltage Formula:

V_supply ≥ V_transmitter + V_load + V_wire + V_margin

Component Voltage Requirements

| Component | Typical Voltage | Notes |

|---|---|---|

| Transmitter (Basic) | 10-12 VDC | Varies by model, check specifications |

| Transmitter (HART) | 12-14 VDC | Higher due to communication circuitry |

| Load Resistor (250Ω) | 1-5 VDC | V = I × R (4-20 mA × 250Ω) |

| Wire Resistance | 0-3 VDC | Depends on cable length and gauge |

| Safety Margin | 2-4 VDC | Compensate supply variation |

| Total Required | 15-28 VDC | Why 24 VDC is industry standard |

Maximum Loop Resistance

Transmitter specifications include maximum loop resistance (R_loop_max):

R_loop_max = (V_supply - V_transmitter_min) / 0.020 A

Example: 24 VDC supply, transmitter requiring 12 VDC minimum:

R_loop_max = (24 - 12) / 0.020 = 600 Ω maximum total loop resistance

This 600Ω includes load resistor + wire resistance + any barriers/isolators

Cable Length Calculations

Determining maximum cable length for given wire gauge:

Wire Resistance Values

- 18 AWG: 6.4 Ω per 1000 ft (21 Ω per 1000 m)

- 20 AWG: 10.1 Ω per 1000 ft (33 Ω per 1000 m)

- 22 AWG: 16.1 Ω per 1000 ft (53 Ω per 1000 m)

- 24 AWG: 25.7 Ω per 1000 ft (84 Ω per 1000 m)

Maximum Distance Formula:

Distance_max = [(R_loop_max - R_load) / (R_wire × 2)] × 1000 ft

(Factor of 2 accounts for supply and return wires)

Example: 600Ω max loop, 250Ω load, 18 AWG wire:

Distance_max = [(600 - 250) / (6.4 × 2)] × 1000 = (350 / 12.8) × 1000 = 27,344 ft (8.3 km)

💡 Practical Range: 4-20mA loops commonly run 500-3,000 ft (150-900 m) with 18-20 AWG wire, providing enormous advantage over voltage signals limited to 100 ft.

🔍 Advantages of 4-20mA Over Other Signal Types

Comparison Table

| Feature | 4-20mA | 0-10V / 0-5V | Digital (Modbus/PROFIBUS) |

|---|---|---|---|

| Max Distance | 1,000+ meters | ~100 meters | 1,000+ meters (depends on protocol) |

| Noise Immunity | Excellent | Poor | Excellent |

| Cable Voltage Drop Impact | None (current constant) | Significant (direct error) | None (digital) |

| Wiring | 2-wire (power + signal) | 3+ wire (separate power) | 2-4 wire + terminators |

| Installation Cost | Low | Low | Medium-High |

| Compatibility | Universal (60+ years) | Universal | Protocol-specific |

| Diagnostics | Basic (underrange/overrange) | None | Advanced |

| Configuration | HART overlay available | Manual (potentiometers) | Built-in |

| Response Time | Fast (10-100 ms typical) | Very Fast (<1 ms) | Moderate (depends on scan rate) |

Why 4-20mA Dominates Industrial Applications

1. Noise Immunity

Current loops resist electrical noise that cripples voltage signals:

- EMI from motors, VFDs, welders doesn’t affect current flow

- Ground loops eliminated (current measurement independent of ground potential)

- Industrial environments with heavy electrical equipment remain noise-free

- No signal degradation over long cable runs

2. Simplicity and Reliability

- Two-wire installation reduces wiring costs 30-50% vs. voltage signals

- No external power supplies at sensor locations

- Proven technology with 60+ years industrial heritage

- Every PLC/DCS natively supports 4-20mA inputs

- Technician familiarity—no specialized training required

3. Self-Diagnostic Capability

- Broken wire detection (0 mA vs. 4 mA live zero)

- Sensor fault signaling (<3.6 mA or >21 mA)

- Visual troubleshooting with handheld milliamp meter

- No ambiguity between zero pressure and failed sensor

📡 HART Protocol: Digital Communication on 4-20mA

What is HART?

HART (Highway Addressable Remote Transducer) superimposes digital communication signals onto 4-20mA analog current without interfering with the analog measurement:

How HART Works

- Digital signal uses frequency shift keying (FSK): 1200 Hz = “1”, 2200 Hz = “0”

- AC signal (0.5 mA amplitude) modulated onto DC current (4-20 mA)

- Average current remains unchanged—analog measurement unaffected

- Digital data provides configuration, diagnostics, status information

- Communication rate: 1200 baud (slow but robust)

HART Capabilities

| Function | 4-20mA Only | 4-20mA + HART |

|---|---|---|

| Pressure Reading | Analog only (4-20 mA) | Analog (4-20 mA) + High-resolution digital (0.001% resolution) |

| Calibration | Manual (test equipment required) | Remote configuration via HART communicator |

| Range Setting | Potentiometer adjustment or DIP switches | Software configuration (set LRV/URV remotely) |

| Diagnostics | Basic (underrange/overrange) | Advanced (sensor health, process diagnostics, alerts) |

| Asset Management | Manual records | Electronic device tags, calibration dates, serial numbers |

| Multiple Variables | Pressure only | Pressure + temperature + diagnostics simultaneously |

HART Implementation in Pressure Transmitters

Point-to-Point Mode

- One transmitter per loop (most common)

- Analog 4-20mA provides primary measurement

- HART used for configuration and diagnostics

- No special wiring—standard 4-20mA connections

- Minimum 250Ω load resistor required for HART signal

Multi-Drop Mode

- Multiple transmitters (up to 15) on single loop

- All transmitters fixed at 4 mA (analog measurement disabled)

- Each transmitter assigned unique address (1-15)

- Digital HART provides all measurements

- Reduces wiring costs in dense instrumentation areas

- Requires HART multiplexer or compatible controller

HART Configuration Example

Scenario: Re-ranging 0-1000 PSI transmitter to 0-500 PSI using HART:

- Connect HART Communicator: Anywhere in loop (transmitter, junction box, I/O card)

- Read Device Tag: Verify correct transmitter identified

- Navigate to Configuration: Select “Set Range” menu

- Enter New Values: LRV = 0 PSI, URV = 500 PSI

- Apply Changes: Transmitter reconfigures instantly

- Verify: Apply test pressure, confirm 250 PSI = 12 mA

⏱️ Time Savings: HART configuration takes 2-5 minutes vs. 30-60 minutes for traditional calibration requiring pressure source, reference gauge, and manual adjustment.

🔧 Installation Best Practices

Wiring Guidelines

Cable Selection

- Shielded Twisted Pair: Recommended for all 4-20mA loops in noisy environments

- 18-22 AWG: Appropriate for most installations (<3000 ft)

- Capacitance: <200 pF/ft for HART compatibility (most cables comply)

- Cable Rating: 600V minimum, appropriate for environment (UV-resistant, chemical-resistant, etc.)

Routing and Segregation

- Run 4-20mA cables in separate conduit from power wiring (120VAC+)

- Maintain 12″ minimum spacing if conduit separation not possible

- Cross power cables at 90° to minimize inductive coupling

- Avoid routing near VFDs, high-power transmitters, welders

- Use steel conduit for additional shielding in extreme EMI environments

Grounding and Shielding

- Shield Grounding: Ground at ONE end only (typically controller end) to prevent ground loops

- Never at Both Ends: Creates ground loop, induces noise rather than preventing it

- Transmitter Grounding: Metal transmitter housings should be grounded per manufacturer instructions

- Intrinsically Safe Circuits: Follow IS barrier grounding requirements (often different from standard practice)

Load Resistor Selection

| Application | Load Resistor | Voltage Range | Reason |

|---|---|---|---|

| PLC Analog Input | Internal (typically 250Ω) | 1-5 VDC | PLC provides resistor, measures voltage |

| DCS Analog Input | Internal or external (250Ω) | 1-5 VDC | Varies by system |

| HART Communication | 250-600Ω | 1-12 VDC | Minimum 250Ω required for HART signal |

| Chart Recorder | External (typically 250Ω) | 1-5 VDC | Converts current to voltage |

| Long Cable Run | Lower value (100-250Ω) | 0.4-5 VDC | Reduces voltage drop, increases distance |

Commissioning Checklist

- ✅ Visual Inspection: Verify correct wiring polarity, secure connections, proper grounding

- ✅ Continuity Test: Measure loop resistance (should match calculated value ±10%)

- ✅ Insulation Test: Megohm test between loop wires and ground (>10 MΩ typical)

- ✅ Power Supply Voltage: Measure at transmitter terminals (should be within specifications)

- ✅ Zero Pressure Test: Vent transmitter to atmosphere, verify 4.00 mA output

- ✅ Span Verification: Apply known pressure, verify correct current output

- ✅ HART Communication: If applicable, connect HART communicator, verify communication

- ✅ Documentation: Record as-found/as-left values, wiring diagram, HART configuration

🔍 Troubleshooting 4-20mA Loops

Common Problems and Diagnostic Procedures

Problem: No Current Reading (0 mA)

Diagnostic Steps:

- Verify Power Supply: Measure voltage at power supply output (should be 24 VDC ±10%)

- Check Wiring Continuity: Ohmmeter test from supply through transmitter back to supply

- Measure at Transmitter: Voltage at transmitter terminals (if 0V, wiring issue; if 24V, transmitter failed)

- Isolation Test: Disconnect transmitter, measure supply voltage (if OK, transmitter short circuit)

Common Causes:

- Broken wire or loose connection (most common)

- Failed power supply

- Transmitter internal failure (short circuit)

- Blown fuse in power supply or barrier

Problem: Low Reading (<4 mA or Fluctuating)

Diagnostic Steps:

- Calculate Loop Resistance: Measure actual resistance, compare to maximum specification

- Check Supply Voltage: Voltage at transmitter should exceed minimum (typically 10-12 VDC)

- Reduce Load Resistance: Temporarily reduce load resistor value or remove unnecessary devices

- Inspect Connections: High-resistance connections cause voltage drop (corrosion, loose screws)

Common Causes:

- Loop resistance too high (cable too long, gauge too small)

- Insufficient supply voltage

- Corroded connections adding resistance

- Marginal transmitter requiring more voltage than specified

Problem: Noisy or Erratic Signal

Diagnostic Steps:

- Ground Loop Check: Measure voltage between cable shield and earth ground (should be <1 VDC)

- EMI Source Identification: Turn off nearby equipment (motors, VFDs) individually to identify noise source

- Shielding Verification: Confirm shield grounded at ONE end only

- Cable Routing Review: Identify parallel runs with power cables, long runs in noisy areas

Common Causes:

- Shield grounded at both ends (ground loop)

- Cable routed near EMI sources (motors, VFDs, welders)

- Unshielded cable in noisy environment

- Poor connections creating intermittent contact

Problem: HART Communication Failure

Diagnostic Steps:

- Verify Load Resistor: Minimum 250Ω required (measure across input terminals)

- Check Cable Capacitance: High capacitance (<200 pF/ft spec) attenuates HART signal

- Remove Parallel Devices: Disconnect surge protectors, isolators during testing

- Test Communication Distance: Try HART communicator at transmitter vs. control room

Common Causes:

- Load resistor <250Ω (HART signal amplitude too low)

- High-capacitance cable or excessive length (>3000 ft HART range limit)

- Parallel devices loading HART signal (surge suppressors, repeaters)

- Transmitter HART function disabled in configuration

💰 Total Cost of Ownership: 4-20mA vs. Alternatives

Lifecycle Cost Comparison (100 Sensors, 10 Years)

| Cost Element | 4-20mA | 0-10V | Digital Fieldbus |

|---|---|---|---|

| Initial Sensor Cost | $50,000 | $40,000 | $80,000 |

| Wiring/Installation | $30,000 | $45,000 | $40,000 |

| Infrastructure (gateways, etc.) | $0 | $0 | $20,000 |

| Commissioning | $10,000 | $12,000 | $25,000 |

| Troubleshooting/Maintenance | $15,000 | $35,000 | $20,000 |

| Downtime Costs | $20,000 | $50,000 | $15,000 |

| 10-Year Total | $125,000 | $182,000 | $200,000 |

💡 Key Takeaway: 4-20mA provides lowest total ownership cost due to installation simplicity, troubleshooting ease, and universal technician familiarity. Digital fieldbus offers advantages (advanced diagnostics, multi-variable transmission) but at 60% cost premium requiring specialized expertise.

🌟 SUCO ESI 4-20mA Pressure Transmitter Solutions

SUCO ESI offers comprehensive 4-20mA pressure transmitter portfolios serving industrial applications worldwide:

Product Range

- ✅ General Purpose Transmitters: Cost-effective 4-20mA output, ±0.5-1.0% accuracy

- ✅ High-Accuracy SoS Transmitters: ±0.25% accuracy with Silicon-on-Sapphire technology

- ✅ HART-Enabled Transmitters: Digital configuration and diagnostics

- ✅ Hazardous Area Transmitters: ATEX/IECEx certified intrinsically safe

- ✅ Sanitary Transmitters: 3-A compliant for food/pharmaceutical applications

- ✅ Extreme Environment: High-temperature, high-pressure designs

Technical Support

- Application Engineering: Loop power calculations, cable sizing, system design

- Commissioning Support: Start-up assistance, HART configuration, troubleshooting

- Training: 4-20mA fundamentals, HART protocol, troubleshooting techniques

- Documentation: Wiring diagrams, loop calculations, configuration sheets

Contact SUCO ESI Today

📞 Phone: 1-800-473-7313

🌐 Website: www.sucoesi.com

📧 Contact: Request Technical Support

Related Resources:

4-20mA pressure transmitters remain the industrial standard for reliable, cost-effective pressure measurement. Understanding current loop fundamentals, proper installation techniques, and advanced HART capabilities ensures optimal system performance and lifecycle value. ⚡

4-20mA Pressure Transmitters