When your excavator, crane, or mobile equipment breaks down because of a faulty pressure switch, you're not just dealing with repair costs: you're facing downtime, missed deadlines, and frustrated crews. Mobile hydraulics operate in some of the most demanding environments imaginable: constant vibration, extreme temperatures, pressure spikes, and contaminated fluids. Your pressure switch isn't just a component: it's a critical safety device that protects expensive pumps, motors, and cylinders from catastrophic failure.

Selecting the right pressure switch for mobile hydraulic applications requires more than checking a pressure rating on a spec sheet. You need to understand how these switches perform under real-world conditions where shock, heat, and hydraulic surges are daily challenges.

Here are the five essential factors you must evaluate when choosing pressure switches for mobile hydraulics.

1. Shock and Vibration Resistance: Built to Handle the Bumps

Mobile equipment doesn't operate on smooth factory floors. Your excavators dig through rocky terrain. Your cranes lift loads while the chassis flexes. Your forestry equipment navigates uneven ground at variable speeds. Every bump, jolt, and impact translates directly to your hydraulic system: and to the pressure switch monitoring it.

A pressure switch that's sensitive to vibration will generate false signals, triggering unnecessary shutdowns or failing to detect genuine pressure problems. This isn't theoretical: it happens on job sites every day.

What makes a pressure switch vibration-resistant?

- Robust mechanical construction with minimal moving parts that can shift or loosen

- Secure electrical connections that won't rattle loose during operation

- Quality housing materials that absorb shock without cracking or deforming

- Proven design specifically engineered for mobile applications

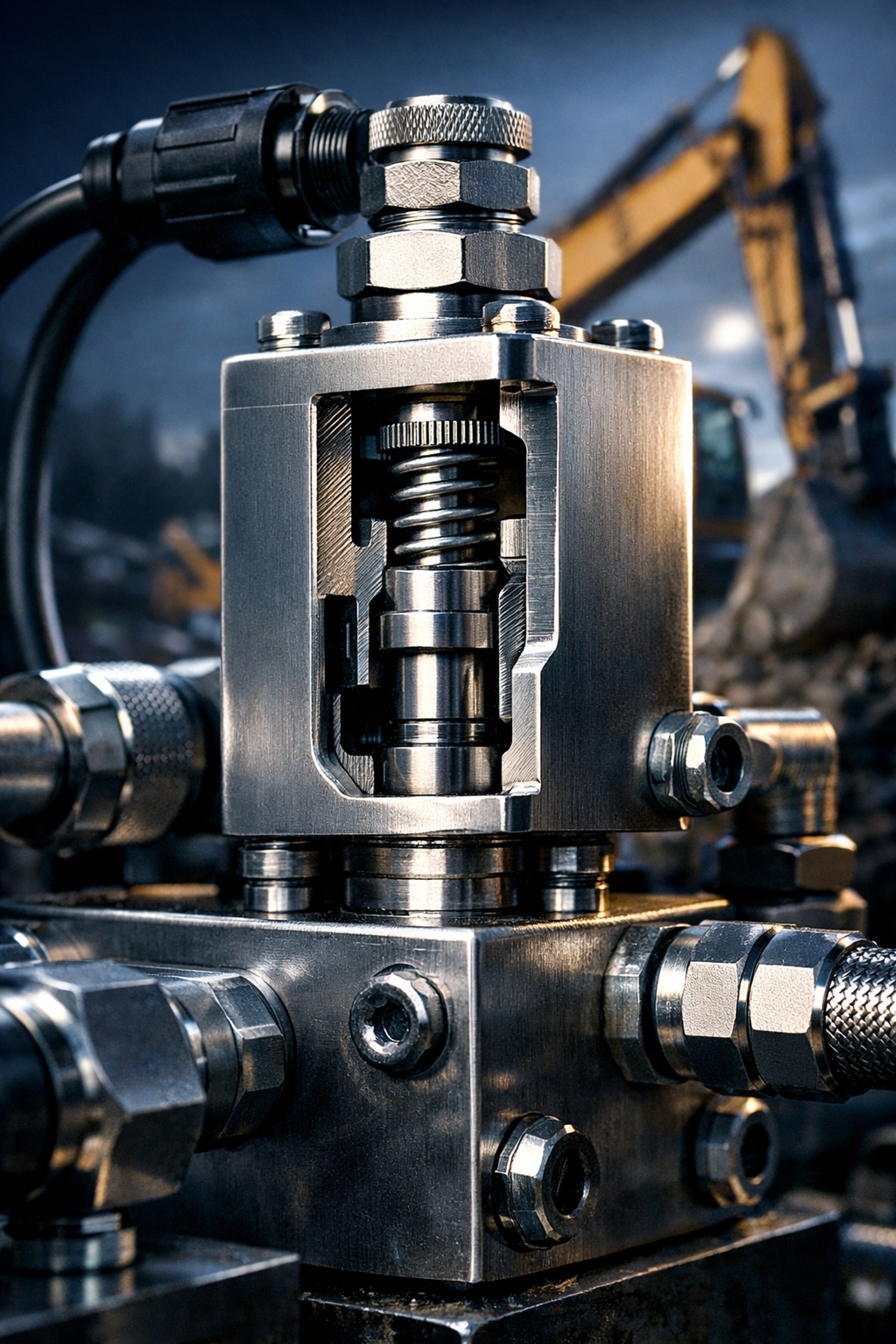

Standard industrial pressure switches designed for stationary equipment simply don't cut it in mobile hydraulics. You need switches that maintain switching accuracy despite constant movement and mechanical stress. Piston-type mechanisms outperform diaphragm designs in mobile applications because they offer superior durability and pressure handling in aggressive operating conditions.

When evaluating switches for mobile equipment, look for specifications that explicitly address vibration resistance: and ask for field performance data from similar applications. A switch that works perfectly on a test bench may fail within weeks in actual mobile service.

2. Lightning-Fast Response Time: Catching Pressure Changes Before Damage Occurs

Mobile hydraulic systems experience rapid pressure fluctuations that would never occur in stationary industrial systems. When a boom suddenly stops, when a load shifts unexpectedly, or when an operator makes a quick control input, pressure can spike in milliseconds.

Your pressure switch must react fast enough to detect these transient events and trigger protective actions before components suffer damage. Industry standards for mobile hydraulics specify response times between 5 to 10 milliseconds for pressure pulse detection.

Slow response times create two critical problems:

- Premature switching that shuts down equipment unnecessarily, reducing productivity

- Failure to detect genuine dangerous pressure spikes, leaving expensive components unprotected

Electronic pressure switches typically offer faster response times than mechanical switches, but they introduce different challenges in harsh mobile environments. The key is finding the right balance between speed, reliability, and environmental resistance for your specific application.

3. Pressure Range and Overpressure Safety: Plan for the Worst-Case Scenario

Here's a mistake we see constantly: engineers select pressure switches based on normal operating pressure without accounting for pressure spikes. Mobile hydraulic systems regularly experience transient pressure events that exceed steady-state pressure by 2x to 4x.

When a hydraulic cylinder reaches the end of its stroke, when a relief valve opens suddenly, or when temperature changes affect fluid viscosity, pressure spikes occur. Your pressure switch must handle these events without damage or calibration drift.

Critical specifications to verify:

- Maximum operating pressure (not just rated pressure)

- Burst pressure rating for worst-case scenarios

- Overpressure safety factor built into the design

- Proof pressure the switch has been tested against

Piston-style pressure sensing mechanisms handle higher pressures and aggressive conditions more reliably than diaphragm designs. The piston provides superior mechanical strength and resistance to pressure fatigue: essential for equipment that may cycle millions of times during its service life.

Don't just match the switch rating to your system pressure. Add significant safety margin to account for transient events, temperature effects, and aging of hydraulic components over time. A pressure switch rated too close to operating pressure is a failure waiting to happen.

4. Environmental Protection and Media Compatibility: Surviving the Elements

Mobile equipment operates outdoors in conditions that would destroy standard industrial components. Rain, mud, dust, road salt, temperature extremes, and hydraulic fluid contamination: your pressure switch faces all of it.

IP (Ingress Protection) ratings tell you how well the switch resists environmental intrusion:

- IP65: Dust-tight and protected against water jets: minimum for most mobile applications

- IP67: Dust-tight and protected against temporary immersion: better for equipment exposed to heavy washdown or wet conditions

- IP69K: Dust-tight and protected against high-pressure, high-temperature washdown: required for food processing equipment and specialized applications

But environmental protection isn't just about the housing. Material compatibility determines whether your switch survives contact with hydraulic fluids across the temperature range your equipment experiences.

Quality pressure switches for mobile hydraulics feature:

- Stainless steel wetted components that resist corrosion from hydraulic fluids and additives

- NBR (nitrile) or Viton seals compatible with petroleum-based and synthetic hydraulic fluids

- Temperature ratings spanning -40°F to 250°F or broader for extreme-climate operation

- Electrical connections sealed against moisture and vibration

We've seen pressure switches fail not from pressure cycling but from seal degradation caused by incompatible hydraulic fluid additives. Always verify material compatibility with the specific fluids you use: not just generic "hydraulic oil."

5. Installation Strategy: Protecting Your Investment

Even the toughest pressure switch benefits from smart installation practices that minimize exposure to shock, vibration, and pressure pulsations. How you install the switch matters as much as which switch you select.

Protective installation strategies include:

Pressure snubbers: Small restrictive fittings installed between the hydraulic system and pressure switch dampen rapid pressure fluctuations while allowing the switch to track genuine pressure changes. Snubbers prevent false triggering without compromising safety monitoring.

Remote mounting with capillary lines: Locating the pressure switch away from high-vibration areas using a small-diameter capillary tube isolates the switch from mechanical stress while maintaining pressure sensing capability. This works exceptionally well for applications with severe vibration.

Mounting location selection: Choose mounting points that minimize exposure to direct mechanical shock and provide some thermal isolation from hot hydraulic components.

Proper orientation: Install switches in orientations that prevent air pockets from forming at the sensing element, which can cause erratic behavior.

Some mobile equipment manufacturers specify protective measures like snubbers or remote mounting as standard practice, recognizing that even premium pressure switches perform better with proper installation support.

Why SUCO Sets the Standard for Mobile Hydraulic Pressure Switches

For over 80 years, SUCO has engineered pressure and temperature switches for the world's most demanding applications. Our switches protect mobile equipment operating in construction, agriculture, forestry, material handling, and specialty vehicles across six continents.

What sets SUCO apart for mobile hydraulics:

- Piston-type sensing mechanisms designed specifically for high-pressure, high-shock mobile applications

- IP67 and IP69K environmental protection for extreme operating conditions

- -40°F to 257°F temperature range accommodating global climate variations

- Stainless steel construction and premium seal materials for long service life

- Overpressure safety factors that protect against transient pressure spikes

- Global certifications including UL, CE, and industry-specific approvals

We don't just sell components: we partner with equipment manufacturers and fleet operators to engineer pressure sensing solutions that deliver reliable performance season after season, year after year. Our engineering team understands the unique challenges of mobile hydraulics because we've solved them thousands of times.

Frequently Asked Questions

What is overpressure safety in a pressure switch?

Overpressure safety refers to the pressure switch's ability to withstand pressure spikes significantly higher than its rated operating pressure without damage or calibration drift. Quality switches include overpressure safety factors of 2x to 4x rated pressure. This protects against transient pressure events common in mobile hydraulics: sudden load changes, rapid valve closures, or temperature-induced pressure increases. Without adequate overpressure protection, switches can fail prematurely or require frequent recalibration.

Should I choose a mechanical or electronic pressure switch for mobile equipment?

Both technologies work in mobile applications, but each offers distinct advantages. Mechanical switches provide proven reliability, no external power requirements, and excellent vibration resistance: ideal for basic on/off pressure monitoring. Electronic pressure switches deliver faster response times, programmable switching points, and integration with control systems: valuable for advanced equipment with electronic controls. Consider your specific requirements: simple reliable switching favors mechanical; rapid response and system integration favor electronic. Many modern mobile machines use both types in different circuits.

How do I determine the right pressure range for my application?

Start with your system's normal operating pressure, then add significant safety margin. Multiply your typical operating pressure by at least 1.5x to 2x to account for pressure spikes, temperature effects, and component aging. Verify the switch's burst pressure rating exceeds worst-case scenarios. For mobile hydraulics operating at 3,000 PSI nominal pressure, select switches rated for 5,000 PSI operating pressure with burst ratings above 10,000 PSI. Never select a switch where operating pressure approaches maximum rated pressure: this guarantees premature failure.

What IP rating do I need for mobile hydraulic applications?

Minimum IP65 for most mobile equipment: this provides dust-tight sealing and water jet resistance adequate for outdoor operation. Upgrade to IP67 for equipment frequently exposed to heavy rain, washdown, or temporary water immersion. Specify IP69K only for specialized applications requiring high-pressure, high-temperature cleaning (food processing equipment, pharmaceutical transport, etc.). Remember that IP ratings apply to proper installation: a poorly sealed electrical connection negates the switch's environmental protection. Always follow manufacturer installation guidelines to maintain rated protection levels.

Protect Your Mobile Equipment With Proven Pressure Switch Technology

Selecting pressure switches for mobile hydraulics isn't about finding the cheapest component: it's about protecting hundreds of thousands of dollars in equipment investment and avoiding costly downtime. The five factors we've outlined: shock resistance, response time, pressure range, environmental protection, and installation strategy: separate switches that perform reliably for years from those that fail prematurely.

SUCO brings over eight decades of pressure sensing expertise to your mobile equipment challenges. Our engineering team helps you select the right pressure switches for your specific application, operating conditions, and performance requirements.

Ready to specify pressure switches that won't let you down? Contact our technical team for application-specific recommendations and support. We'll help you protect your equipment investment with pressure sensing solutions proven in the world's toughest mobile applications.

Connect with us on LinkedIn for industry insights and follow our YouTube channel for technical videos and product demonstrations.