When your hydraulic excavator starts acting up or your HVAC compressor won’t kick on at the right pressure, the culprit is often a simple pressure switch adjustment. You don’t need to call a technician or replace the entire unit, most pressure switch adjustments take just five minutes with the right approach.

Whether you’re managing a fleet of construction equipment, maintaining HVAC systems, or keeping automotive hydraulics running smoothly, knowing how to adjust pressure switch settings quickly can save you serious downtime and repair costs.

Why Pressure Switch Adjustment Matters

Why Pressure Switch Adjustment Matters

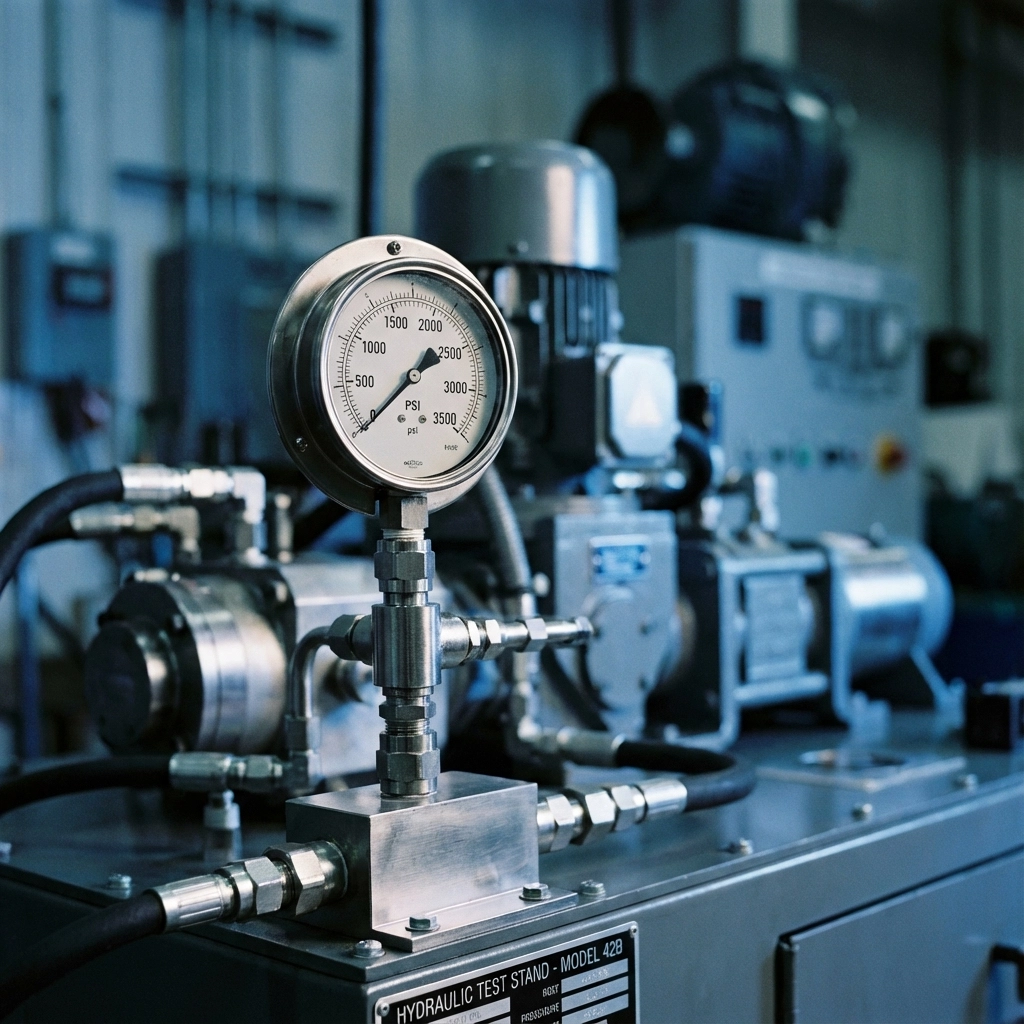

Pressure switches are the unsung heroes of industrial equipment. They protect expensive pumps from damage, ensure consistent system performance, and prevent costly breakdowns. In construction equipment alone, a properly calibrated pressure switch can mean the difference between completing a job on schedule or facing expensive hydraulic system failures.

The most common signs you need an adjustment:

- Equipment cycling too frequently

- Pumps running continuously without shutting off

- System pressure too high or too low

- Inconsistent performance across operating cycles

Safety First: Essential Precautions

Before touching any adjustment screws, complete these safety steps:

- Disconnect all electrical power to the pressure switch and associated equipment

- Fully depressurize the system using proper bleeding procedures

- Wear safety glasses and gloves to protect against fluid spray

- Document your starting position by measuring the distance from exposed threads to nut tops

Critical safety note: High-pressure systems can cause serious injury. If you’re working with pressures above 500 PSI or unfamiliar equipment, consult with a qualified technician.

The 5-Minute Adjustment Process

Step 1: Identify Your Adjustment Points (30 seconds)

Every mechanical pressure switch has two key adjustment mechanisms:

- Large adjustment nut (typically 3/8″ hex) = Controls cut-in pressure and overall range

- Small adjustment nut (typically 1/4″ hex) = Controls differential (cut-out pressure)

Pro tip: Take a photo before making any adjustments. This gives you a visual reference if you need to return to original settings.

Step 2: Understand the Adjustment Direction (30 seconds)

Remember this simple rule:

- Clockwise rotation = Higher pressure (approximately 2-3 PSI per full turn)

- Counterclockwise rotation = Lower pressure (approximately 2-3 PSI per full turn)

Important: When you adjust the large nut for cut-in pressure, the cut-out pressure moves proportionally. You’re essentially shifting the entire pressure range up or down.

Step 3: Adjust Cut-In Pressure (2 minutes)

Using a 3/8″ nut driver or socket:

- Make small adjustments first, no more than one full turn initially

- Turn clockwise to increase the pressure at which your system activates

- Turn counterclockwise to decrease activation pressure

- Count your turns so you can track changes precisely

For construction equipment: Higher cut-in pressures (150-200 PSI) typically provide better performance for heavy-duty hydraulic applications. Construction pressure switches are specifically designed to handle these demanding environments.

For HVAC systems: Standard residential systems usually operate between 20-40 PSI cut-in, while commercial systems may require 40-60 PSI depending on building height and system design.

Step 4: Fine-Tune Differential Pressure (1 minute)

The small adjustment nut controls your system’s pressure differential, the gap between cut-in and cut-out pressures.

Typical differential settings:

- HVAC residential: 15-20 PSI differential

- Automotive/mobile hydraulics: 25-50 PSI differential

- Construction equipment: 30-75 PSI differential

Turn the small nut clockwise to increase the cut-out pressure (wider differential) or counterclockwise to decrease it (tighter differential).

Step 5: Test and Verify (1 minute)

- Reconnect power and slowly pressurize the system

- Monitor activation points with a calibrated pressure gauge

- Verify both cut-in and cut-out pressures match your requirements

- Check for proper system cycling under normal load conditions

Industry-Specific Adjustment Tips

Automotive and Mobile Hydraulics

High-vibration environments require special attention to pressure switch mounting and calibration. For mobile hydraulic systems, set cut-in pressures 10-15% higher than your minimum operating requirements to account for dynamic loading.

Temperature compensation is critical, hydraulic fluid pressure changes with temperature. Adjust during normal operating temperature conditions, not when the system is cold.

Construction Equipment Applications

Harsh environments demand robust settings. Construction equipment typically benefits from:

- Higher differential settings (40-75 PSI) for reduced cycling

- Conservative cut-in pressures to prevent over-pressurization during peak loads

- Regular recalibration due to dust and debris affecting switch mechanisms

Seasonal adjustments may be necessary as hydraulic fluid viscosity changes with temperature affect system pressure characteristics.

HVAC and Building Systems

Energy efficiency depends on proper pressure switch calibration. For optimal performance:

- Match cut-in pressure to your system’s minimum effective operating pressure

- Minimize differential to reduce energy waste from over-pressurization

- Consider building load variations when setting cut-out pressures

Multi-zone systems may require different pressure switch settings for different areas of the building.

Troubleshooting Common Issues

Switch won’t adjust or feels stuck: Mineral deposits or corrosion may be binding the adjustment mechanism. Clean threads with appropriate solvents before forcing adjustments.

Pressure readings inconsistent: Check your pressure gauge calibration and ensure proper gauge placement in the system.

System short-cycling after adjustment: Your differential may be set too narrow. Increase the gap between cut-in and cut-out pressures.

No response to adjustments: Internal switch components may be damaged. Consider replacement with quality adjustable pressure switches designed for your specific application.

When Professional Help Makes Sense

Call a qualified technician if:

- Working with pressures above 500 PSI

- Dealing with hazardous fluids or gases

- Switch adjustment doesn’t resolve the underlying problem

- You’re uncomfortable with system safety procedures

SUCO ESI North America provides expert technical support for complex pressure switch applications. Our team understands the unique challenges faced by professionals in automotive, construction, and HVAC industries. Contact sales@sucoesi.com

Maintenance Best Practices

Regular calibration prevents major problems. Establish a maintenance schedule based on:

- Operating environment severity (dust, temperature extremes, vibration)

- System criticality (production equipment vs. auxiliary systems)

- Manufacturer recommendations for your specific pressure switch model

Documentation is essential. Keep records of:

- Original factory settings

- Adjustment dates and reasons

- System performance before and after changes

- Environmental conditions during adjustments

Follow us on LinkedIn for the latest pressure switch maintenance tips and industry updates.

Frequently Asked Questions

Q: How often should I adjust my pressure switch?

A: Most pressure switches maintain calibration for 6-12 months in normal conditions. High-vibration or contaminated environments may require quarterly adjustments.

Q: Can I adjust my pressure switch while the system is running?

A: No. Always disconnect power and depressurize the system completely before making adjustments. Live adjustments are extremely dangerous and can damage equipment.

Q: What’s the difference between cut-in and cut-out pressure?

A: Cut-in pressure is when the switch activates your pump or system. Cut-out pressure is when it deactivates. The difference between these two pressures is called the differential.

Q: Why does my system keep cycling on and off rapidly?

A: This typically indicates your differential pressure setting is too narrow, or there may be a leak in the system causing rapid pressure loss.

Q: Can weather affect my pressure switch settings?

A: Yes, temperature changes affect fluid pressure. Systems exposed to extreme temperature variations may need seasonal adjustments for optimal performance.

Q: What tools do I need for pressure switch adjustment?

A: Most adjustments require a 3/8″ and 1/4″ nut driver or socket set, safety glasses, gloves, and a calibrated pressure gauge for verification.

Q: How do I know if my pressure switch needs replacement instead of adjustment?

A: If adjustments don’t hold, the switch feels mechanically damaged, or you can’t achieve proper pressure settings despite multiple attempts, replacement is likely necessary.

Get Expert Support for Your Pressure Switch Needs

Don’t let pressure switch problems slow down your operations. Whether you’re managing construction equipment, automotive hydraulics, or HVAC systems, proper pressure switch adjustment keeps your equipment running efficiently and prevents costly downtime.

Need help selecting the right pressure switch for your application? Our technical team at SUCO ESI North America brings decades of experience helping professionals in demanding industrial environments. We provide expert guidance on pressure switch selection, installation, and maintenance for automotive, construction, and HVAC applications.

Contact us today for personalized technical support, product recommendations, or to request a quote for your specific pressure switch requirements. Let our expertise keep your critical systems operating at peak performance.