When standard pressure sensors fail in extreme environments—whether at 200°C in oil & gas downhole applications, under 20,000 PSI in hydrogen fuel systems, or after years of operation drifting beyond acceptable accuracy—engineers turn to Silicon-on-Sapphire pressure sensors. This advanced technology eliminates the fundamental failure mechanisms plaguing conventional piezoresistive sensors by molecularly bonding silicon strain gauges directly to sapphire substrates, creating measurement devices with unprecedented long-term stability (<0.2% over 10+ years), extreme temperature capability (-40°C to 300°C+), and mechanical ruggedness that withstands applications where traditional sensors simply cannot survive.

Understanding Silicon-on-Sapphire: The Science Behind Superior Performance

What Makes Silicon-on-Sapphire Technology Different?

Silicon-on-Sapphire pressure sensors represent a fundamental departure from conventional piezoresistive sensor construction. While traditional sensors bond silicon strain gauges to steel or silicon diaphragms using adhesives or glass frits that degrade over time, SoS technology uses epitaxial crystal growth to create a molecular bond between silicon and sapphire—literally growing silicon atoms directly onto the sapphire crystal lattice.

The Molecular Bonding Advantage

This molecular-level integration creates a monolithic structure where:

- ✅ No bonding agents exist to degrade, eliminating the #1 cause of sensor drift

- ✅ Thermal expansion mismatches disappear since silicon and sapphire are bonded at atomic level

- ✅ Mechanical stress coupling is perfect ensuring accurate pressure-to-resistance conversion

- ✅ Temperature compensation simplifies due to inherent material property matching

- ✅ Chemical barriers eliminate contamination pathways present in conventional designs

The Result: Silicon-on-Sapphire sensors achieve 5-10x better long-term stability, 2-3x wider temperature ranges, and virtually zero hysteresis compared to standard piezoresistive alternatives.

Sapphire: The Ideal Substrate Material

Sapphire (crystalline aluminum oxide, Al₂O₃) provides exceptional properties that make it the optimal pressure sensor substrate:

| Property | Sapphire | Silicon | Stainless Steel | Advantage |

|---|---|---|---|---|

| Hardness (Mohs) | 9 (second only to diamond) | 6-7 | 5-6 | Superior scratch, abrasion, and impact resistance |

| Chemical Inertness | Inert to acids, bases, solvents | Limited (Si etched by KOH) | Moderate (corrodes) | Universal media compatibility without degradation |

| Max Temperature | 2000°C melting point | 1414°C melting | ~1400°C | Enables extreme temperature operation to 300°C+ |

| Thermal Stability | Very low thermal expansion | Higher expansion | High expansion | Minimal temperature-induced stress and drift |

| Electrical Insulation | Excellent insulator | Semiconductor | Conductor | Prevents electrical leakage and noise |

| Optical Transparency | UV to IR transparent | IR transparent only | Opaque | Enables optical inspection and advanced diagnostics |

🔍 Engineering Insight: Sapphire’s 9 Mohs hardness means it resists scratching from virtually all industrial materials except diamond, cubic boron nitride, and other sapphires—critical for sensors exposed to abrasive slurries, particulate-laden gases, or harsh process streams that would rapidly degrade softer materials.

Silicon-on-Sapphire Sensor Construction and Manufacturing

Epitaxial Growth Process

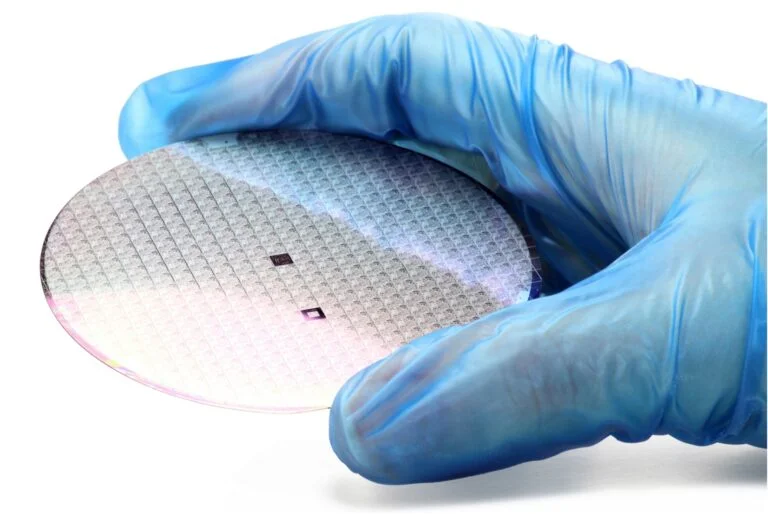

Creating Silicon-on-Sapphire pressure sensors requires sophisticated semiconductor manufacturing techniques:

Step 1: Substrate Preparation

High-purity sapphire wafers are precision-polished to atomic-level smoothness (roughness <0.5 nm RMS), then heated to 1000-1200°C in ultra-high vacuum chambers to remove surface contamination and create perfectly ordered crystal surfaces.

Step 2: Silicon Epitaxy

Silicon atoms are deposited onto the sapphire surface using chemical vapor deposition (CVD) at temperatures around 1000°C. Under these conditions, silicon atoms bond directly to the sapphire crystal lattice, forming a continuous crystalline silicon layer 0.5-2 microns thick. This epitaxial process creates the molecular bond that eliminates adhesive degradation issues.

Step 3: Strain Gauge Patterning

Using photolithography and ion implantation (similar to integrated circuit manufacturing), piezoresistive strain gauges are created within the epitaxial silicon layer. These gauges are configured as a Wheatstone bridge that converts mechanical strain from pressure-induced diaphragm deflection into electrical resistance changes.

Step 4: Diaphragm Formation

The sapphire substrate is precision-machined (laser cutting, ultrasonic machining, or chemical etching) to create a thin diaphragm (50-500 microns depending on pressure range) that deflects under applied pressure while the thicker rim provides mechanical support.

Step 5: Assembly and Packaging

The SoS sensing element is mounted into stainless steel or specialty alloy housings, electrically connected, and sealed to create complete pressure sensors meeting environmental protection standards (IP65-IP68). SUCO ESI’s HI2000 series exemplifies this integration with ATEX-certified housings for hazardous area applications.

Quality Control and Testing

Every Silicon-on-Sapphire pressure sensor undergoes rigorous testing:

- Temperature Cycling: -40°C to +125°C (or rated maximum) for 100+ cycles verifying stability

- Pressure Cycling: 1 million+ cycles from zero to full scale confirming fatigue resistance

- Long-term Drift Testing: Extended testing at elevated temperature documenting <0.2% stability

- Burst Pressure Testing: Destructive testing to 3-5x rated pressure verifying safety margins

- EMI/RFI Testing: Electromagnetic compatibility verification per applicable standards

- Calibration Certification: NIST-traceable calibration with documented accuracy at multiple points

Performance Comparison: Silicon-on-Sapphire vs. Conventional Sensors

Long-Term Stability: The Defining Advantage

The most significant benefit of Silicon-on-Sapphire pressure sensors is exceptional long-term stability eliminating frequent recalibration:

| Time Period | Silicon-on-Sapphire Drift | Standard Piezoresistive Drift | Calibration Savings |

|---|---|---|---|

| 1 Year | <0.05% FS | 0.5-1.0% FS | Annual calibration eliminated |

| 5 Years | <0.1% FS | 2.5-5.0% FS (often out of spec) | 4 calibration cycles avoided ($2,000-$10,000) |

| 10 Years | <0.2% FS | 5-10% FS (replacement required) | 9 calibrations + 1 replacement ($5,000-$25,000) |

| 15+ Years | <0.3% FS (still in spec) | N/A (sensor replaced multiple times) | Total ownership cost 40-60% lower |

ROI Example: An offshore oil platform with 200 pressure sensors spending $500 per calibration saves $100,000 annually switching from annual to 5-year calibration intervals. Over 10 years, the platform saves $900,000 in calibration costs plus $200,000-$500,000 in avoided replacements—despite SoS sensors costing 2-3x more initially.

Temperature Performance Comparison

Temperature affects sensor accuracy through multiple mechanisms—zero drift, span drift, and nonlinearity changes. Silicon-on-Sapphire pressure sensors dramatically outperform conventional alternatives:

Operating Temperature Range

- Standard Piezoresistive: -40°C to +125°C typical maximum

- Silicon-on-Sapphire: -40°C to +200°C standard, +300°C special designs

- Advantage: 60-140% wider temperature range enabling previously impossible applications

Temperature Coefficient of Zero (TCZ)

- Standard Piezoresistive: ±0.02% to ±0.05% FS per °C requiring complex compensation

- Silicon-on-Sapphire: ±0.01% to ±0.02% FS per °C with simpler compensation

- Advantage: 50% better thermal zero stability reducing electronic complexity

Temperature Coefficient of Span (TCS)

- Standard Piezoresistive: ±0.02% to ±0.03% reading per °C

- Silicon-on-Sapphire: ±0.01% to ±0.015% reading per °C

- Advantage: 40-50% better span stability across temperature extremes

Real-World Impact: Downhole pressure sensors experience 150°C+ temperature swings during drilling operations. SoS technology maintains ±0.25% accuracy while conventional sensors drift 2-5% requiring frequent recalibration or accepting degraded accuracy.

Hysteresis and Repeatability

| Performance Metric | Silicon-on-Sapphire | Standard Piezoresistive | Impact on Application |

|---|---|---|---|

| Hysteresis | <0.02% FS typical | 0.1-0.5% FS typical | SoS eliminates directional errors in pressure cycling |

| Repeatability | ±0.01% FS | ±0.05% FS | 5x better consistency for precision control loops |

| Resolution | 0.001% FS achievable | 0.01-0.05% FS typical | 10-50x finer pressure detection enabling advanced control |

⚡ Control System Benefit: Virtually zero hysteresis eliminates “dead band” issues in closed-loop control systems, enabling tighter process control, reduced oscillation, and better product quality in pharmaceutical manufacturing, semiconductor fabrication, and precision hydraulic systems.

Applications Where Silicon-on-Sapphire Technology Excels

Oil & Gas: Extreme Pressure and Temperature

Downhole Pressure Monitoring

Oil wells reach depths of 30,000+ feet where temperatures exceed 200°C and pressures approach 30,000 PSI. Retrieving failed sensors costs $500,000-$2,000,000 per intervention, making reliability paramount. Silicon-on-Sapphire pressure sensors enable:

- 15+ year service life without replacement in permanent downhole installations

- 200°C continuous operation where conventional sensors fail within months

- <0.2% drift maintaining formation pressure accuracy for reservoir management

- Shock/vibration resistance surviving drill string impacts and well intervention operations

Subsea Production Systems

Subsea sensors at 9,000+ meter depths face 13,000+ PSI hydrostatic pressure, 0-150°C temperature extremes, saltwater corrosion, and zero maintenance access for 20+ years. SoS technology provides:

- Sapphire’s chemical inertness resisting seawater corrosion indefinitely

- Long-term stability eliminating drift-induced safety margin erosion

- Wide operating range handling both installation (ambient) and operating (elevated) conditions

- Proven reliability in critical safety systems preventing blowouts

Aerospace: Reliability Over Decades

Commercial Aircraft Pressure Systems

Aircraft operate 30+ years with pressure sensors experiencing:

- Temperature cycling: -65°C at cruise altitude to +125°C in engine bays (thousands of cycles)

- Vibration exposure: 10-2000 Hz at 10-20g acceleration continuously

- Pressure cycling: Cabin pressurization 6-8 PSI differential 30,000+ cycles over service life

- Maintenance intervals: 5-10 year replacement cycles requiring exceptional stability

Silicon-on-Sapphire pressure sensors meet stringent aerospace requirements:

- AS9100D quality management compliance with full traceability

- DO-160 environmental qualification (temperature, vibration, EMI, altitude)

- Sapphire’s mechanical strength providing inherent vibration resistance

- Long-term stability eliminating in-service drift and calibration requirements

- Heritage in 10,000+ flight hours demonstrating proven reliability

Hydrogen Economy: Safety-Critical Measurement

The emerging hydrogen economy creates unprecedented pressure sensing challenges:

Hydrogen Fuel Cell Vehicles (700 bar / 10,150 PSI)

Silicon-on-Sapphire pressure sensors address unique hydrogen challenges:

- Hydrogen Permeation Resistance: Sapphire’s dense crystal structure blocks hydrogen diffusion through sensing element (combined with gold-plated diaphragms)

- Embrittlement Immunity: No adhesive bonds to fail from hydrogen-induced cracking

- Long-term Stability: 15-20 year automotive service life without drift in critical safety system

- Fast Response: Real-time pressure monitoring during rapid refueling (3-5 minutes to fill 5 kg tank)

- Safety Certification: ATEX/IECEx Zone 0/1 approval for explosive atmosphere use

Industrial Hydrogen Production (Electrolyzers)

Electrolyzer systems operate at 30-80 bar producing 99.999% pure hydrogen requiring contamination-free sensors:

- Sapphire’s chemical inertness prevents contamination of ultra-pure hydrogen

- High-temperature capability (up to 200°C for high-temperature electrolysis)

- Corrosion resistance to alkaline electrolytes (KOH) and acidic environments (PEM)

- Long calibration intervals reducing maintenance in continuous production facilities

Process Industries: Precision and Reliability

Pharmaceutical Manufacturing

FDA-regulated pharmaceutical processes demand:

- ±0.25% accuracy for critical process parameters affecting drug efficacy

- CIP/SIP capability: Withstand 140°C steam sterilization cycles repeatedly

- Contamination prevention: Sapphire’s inertness prevents leachables entering product

- Long-term stability: Extended validation periods without recalibration

- 3-A sanitary compliance: Appropriate for direct product contact

Semiconductor Fabrication

Chip manufacturing processes require extreme precision:

- Ultra-pure process gases (corrosive fluorine compounds, silanes, arsine) requiring chemically inert sensors

- Vacuum processes (10⁻⁶ to 10⁻⁹ mbar) needing absolute pressure sensors with wide dynamic range

- Thermal processes (CVD reactors at 600-1000°C) requiring high-temperature capability

- Clean room environments (ISO Class 1-5) demanding particle-free sensor construction

Selecting the Right Silicon-on-Sapphire Sensor

When to Specify SoS Technology

Silicon-on-Sapphire pressure sensors provide maximum value when applications feature:

✅ Specify SoS When:

- Operating temperatures exceed 125°C or fall below -40°C frequently

- Temperature cycling range exceeds 100°C (e.g., -20°C to +150°C)

- Accuracy specifications tighter than ±0.5% required

- Calibration intervals must exceed 2-3 years due to cost or accessibility

- Sensor replacement costs exceed $10,000 (offshore, subsea, downhole, aerospace)

- Application involves corrosive media attacking standard sensor materials

- Hydrogen service requiring embrittlement resistance

- Extreme vibration/shock environments (construction, aerospace, mobile equipment)

- Safety-critical applications (SIL 2/3) requiring highest reliability

- 10+ year service life requirement

❌ Standard Sensors May Suffice When:

- Operating temperature always within -20°C to +80°C

- Accuracy requirements ≥±1.0% adequate

- Annual calibration acceptable and cost-effective

- Sensor replacement simple and inexpensive (<$200 total cost)

- Non-critical monitoring applications

- Short service life (1-3 years) acceptable

SUCO Silicon-on-Sapphire Products

HI5000 Series: Extreme Environment Specialists

HI5000 Series: Extreme Environment Specialists

- Pressure Range: 0-5,000 PSI to 0-29,000 PSI

- Temperature: -40°C to +200°C continuous

- Applications: Oil & gas downhole, geothermal, deep-sea

- Features: Compact 58mm diameter, titanium construction, <0.2% stability

- Learn More: HI5000 Downhole Transducers

HI2000 Series: High-Precision Workhorses

HI2000 Series: High-Precision Workhorses

- Pressure Range: 0-100 PSI to 0-10,000 PSI

- Temperature: -40°C to +125°C standard

- Applications: Process control, hydraulics, aerospace

- Features: ±0.25% accuracy, ATEX certified, multiple outputs

- Learn More: HI2000 High-Precision Transducers

GS4200H Series: Hydrogen Specialists

GS4200H Series: Hydrogen Specialists

- Pressure Range: 0-5,000 PSI to 0-15,000 PSI

- Temperature: -40°C to +125°C

- Applications: Fuel cells, H₂ production, refueling stations

- Features: Gold-plated diaphragm, H₂ tested per ISO 11114-2, ATEX Zone 0/1

- Learn More: GS4200H Hydrogen Sensors

Frequently Asked Questions

Q: How much more expensive are Silicon-on-Sapphire pressure sensors?

A: SoS sensors typically cost 2-4x more than equivalent standard piezoresistive sensors initially (e.g., $1,200 vs. $400). However, total ownership costs over 10 years are 40-60% lower due to extended calibration intervals (5+ years vs. annual), longer service life (15+ years vs. 5-8 years), and elimination of premature failures. For critical applications with high replacement costs (offshore, subsea, downhole, aerospace), ROI is achieved in 1-3 years.

Q: Can Silicon-on-Sapphire sensors be repaired or recalibrated?

A: Yes, SoS sensors can be recalibrated following standard procedures. The key advantage is calibration frequency—every 5-10 years instead of annually for standard sensors. Repairs depend on failure mode: electronic failures can often be repaired, while diaphragm damage (from extreme overpressure or impact) typically requires factory replacement. SUCO ESI offers repair and recalibration services with NIST-traceable standards.

Q: Do SoS sensors require special installation procedures?

A: Installation procedures for SoS sensors are identical to standard pressure sensors—proper torque on process connections, appropriate electrical wiring, and environmental protection. One consideration: sapphire is harder but more brittle than steel, so avoid dropping sensors onto hard surfaces and use proper mounting techniques. Follow manufacturer torque specifications to prevent mechanical stress-induced zero shifts.

Q: What happens if a Silicon-on-Sapphire sensor experiences overpressure?

A: SoS sensors typically have burst pressure ratings 3-5x full scale (e.g., 15,000 PSI burst for 5,000 PSI sensor). Brief overpressure events within 2x full scale usually cause no permanent damage. Sustained overpressure 2-3x full scale may cause permanent zero or span shift requiring recalibration. Overpressure exceeding burst rating causes diaphragm fracture and sensor failure—same as any pressure sensor. For applications with frequent pressure spikes, specify sensors with appropriate overpressure protection or install inline snubbers.

Q: Are Silicon-on-Sapphire sensors available in sanitary designs?

A: Yes, SUCO ESI offers SoS sensors with sanitary process connections (tri-clamp, DIN 11851) and 3-A compliant designs for pharmaceutical and food & beverage applications. These sensors withstand repeated CIP (clean-in-place) and SIP (steam-in-place) cycles at 140°C without degradation. The sapphire sensing element’s chemical inertness and high-temperature capability make it ideal for sanitary processes requiring both precision and cleanliness.

Q: How does Silicon-on-Sapphire technology compare to thin-film sensors?

A: Thin-film sensors deposit metal strain gauges onto steel diaphragms, offering improvements over bonded foil gauges but still using adhesives subject to degradation. SoS technology eliminates adhesives entirely through molecular bonding, providing superior long-term stability (<0.2% vs. 0.5-1% annually), higher temperature capability (300°C vs. 150°C), and better chemical resistance. Thin-film sensors cost less initially but don’t achieve SoS performance levels in extreme applications.

Partner with SUCO ESI: Silicon-on-Sapphire Technology Leaders

For over 40 years, SUCO ESI has pioneered Silicon-on-Sapphire pressure sensor applications across the world’s most demanding industries. Our expertise extends beyond manufacturing to application engineering, helping customers solve complex measurement challenges with proven SoS technology.

Why Specify SUCO ESI SoS Sensors?

- ✅ Proven Reliability: Thousands of installations operating 10-20+ years

- ✅ Comprehensive Certifications: ATEX, IECEx, AS9100, ISO 9001, CSA, UL

- ✅ Custom Solutions: Engineering support for unique requirements

- ✅ North American Manufacturing: Fast delivery from St. Louis, MO and Deerfield Beach, FL

- ✅ Global Support: Serving Canada, USA, Mexico, and 30+ countries

- ✅ Technical Expertise: Real engineers with decades of experience

Get Expert Guidance Today

Whether you’re evaluating SoS technology for a new project or troubleshooting performance issues with existing sensors, SUCO ESI’s team provides the expertise to optimize your pressure measurement systems.

📞 Phone: 1-800-473-7313

🌐 Website: www.sucoesi.com

📧 Contact: Request Technical Support

💼 LinkedIn: Connect with SUCO ESI

Related Resources:

- Complete Guide to Electrical Pressure Sensors

- Silicon-on-Sapphire Technology Overview

- Download Technical Datasheets

Silicon-on-Sapphire pressure sensors represent the pinnacle of pressure measurement technology, eliminating fundamental limitations of conventional sensors through advanced materials science and sophisticated manufacturing. When accuracy, reliability, and long-term stability matter most—in oil & gas, aerospace, hydrogen economy, and process industries—SoS technology delivers unmatched performance and lifecycle value.