Florida’s extreme summer heat puts HVAC systems to the test. As temperatures soar past 95°F with intense humidity, reliable Mechanical and Electronic Pressure Switches; play a critical role in preventing system failures and maintaining indoor comfort.

SUCO ESI North America brings over 80 years of German engineering expertise to meet the needs of Florida’s demanding climate—and beyond. Our pressure measurement solutions are trusted by commercial buildings, residential complexes, and industrial facilities across Florida, the USA, Canada, and Mexico. Whether you’re dealing with intense summer heat or year-round pressure demands, SUCO ensures your HVAC systems perform at their best, without failure.

Why Florida’s Climate Demands Superior HVAC Pressure Switches

Temperature Extremes and System Cycling

Florida HVAC systems operate under constant stress that contractors in northern climates rarely experience. Air conditioning units in Miami, Tampa, Orlando, and Jacksonville run 8-10 months per year, creating:

- 3,000-4,000 annual operating hours vs. 1,500-2,000 in temperate zones

- Frequent pressure cycling from continuous on/off operation

- Elevated refrigerant pressures due to extreme outdoor ambient temperatures

- Accelerated component wear requiring more reliable switching technology

Coastal Corrosion Challenges

Properties within 10 miles of Florida’s 1,350 miles of coastline face aggressive salt spray conditions that destroy standard electrical components. SUCO ESI North America’s pressure switches feature:

- 316L stainless steel construction providing superior corrosion resistance

- IP65-IP68 environmental protection sealing out moisture and contaminants

- Gold-plated electrical contacts preventing oxidation and connection failures

- Hermetically sealed designs protecting sensitive switching mechanisms

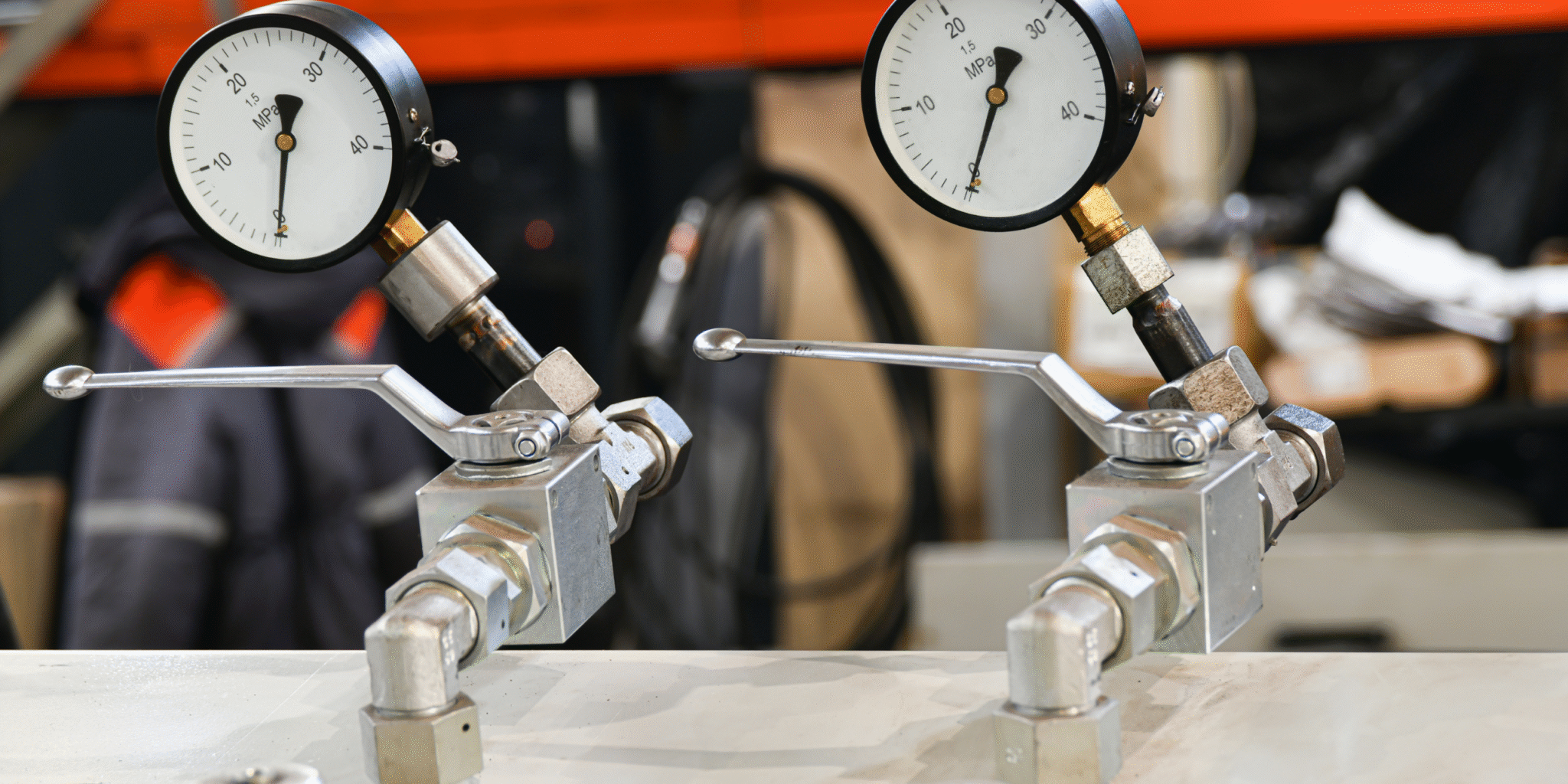

Understanding Mechanical vs. Electronic Pressure Switches for HVAC Applications

Selecting between mechanical and electronic switches for AC and HVAC systems requires understanding each technology’s strengths, limitations, and ideal applications within modern climate control systems.

Mechanical Pressure Switches: Proven Reliability

Mechanical Pressure Switches: Proven Reliability

Mechanical pressure switches use a spring-loaded diaphragm or piston that physically moves to activate electrical contacts when pressure reaches setpoints. This simple, time-tested design offers:

✅ No external power required – Ideal for fail-safe safety applications

✅ Extremely durable – Proven 10-15 year service life in HVAC applications

✅ Wide temperature range – Operates reliably from -40°F to 250°F

✅ Lower cost – 30-50% less expensive than electronic alternatives

✅ Simple installation – Direct replacement without programming or calibration

Best Applications for Mechanical Switches

- High/low refrigerant pressure cutouts preventing compressor damage

- Oil pressure safety switches on commercial chillers

- Water pressure protection in hydronic heating/cooling systems

- Simple on/off control applications without remote monitoring needs

Electronic Pressure Switches: Advanced Control and Monitoring

Electronic pressure switches utilize advanced sensor technology; including SUCO’s proprietary Silicon-on-Sapphire (SoS) sensors to provide digital output signals with superior accuracy and functionality:

✅ ±0.25% accuracy vs. ±2-3% for mechanical switches

✅ Multiple setpoint programming enabling complex control sequences

✅ Analog output signals (4-20mA, 0-10V) for continuous monitoring

✅ Digital communication supporting BACnet, Modbus, and building automation integration

✅ Diagnostic capabilities providing predictive maintenance alerts

Silicon-on-Sapphire Technology: The SUCO ESI Advantage

Our SoS sensor technology delivers performance that traditional piezoresistive sensors cannot match:

| Performance Factor | Silicon-on-Sapphire | Standard Piezoresistive |

|---|---|---|

| Long-term Stability | <0.2% drift over 10 years | 0.5-1.0% annual drift |

| Temperature Compensation | Minimal drift across range | Requires complex circuitry |

| Hysteresis | Virtually zero | 0.1-0.5% typical |

| Vibration Resistance | Sapphire hardness (9 Mohs) | Moderate |

| Chemical Resistance | Sapphire inertness | Limited by adhesives |

This technological superiority translates directly to reduced maintenance costs, fewer false alarms, and extended equipment life for Florida’s commercial HVAC installations.

🔧 Selection Guide: Choosing the Right Pressure Switch for Your Florida HVAC System

Proper selection of mechanical and electronic switches for AC and HVAC systems requires evaluating multiple technical and environmental factors specific to your application.

Proper selection of mechanical and electronic switches for AC and HVAC systems requires evaluating multiple technical and environmental factors specific to your application.

1. Pressure Range Requirements

Always size switches to operate at 60-70% of full scale for optimal accuracy and service life:

- Residential AC systems: 0-500 PSI (high side), 0-150 PSI (low side)

- Commercial chillers: 0-300 PSI (water side), 0-600 PSI (refrigerant)

- Industrial refrigeration: 0-500 PSI standard, up to 3,000 PSI for CO2 systems

2. Refrigerant Compatibility

Florida’s transition to low-GWP refrigerants demands compatible materials:

- R-410A (most common residential): Standard 316L stainless steel

- R-32 (newer systems): Requires specific seal materials

- R-454B, R-1234ze (commercial): Verify compatibility with manufacturer

- Ammonia (R-717): Specialized materials, SUCO ESI provides NH3-compatible options

3. Environmental Protection Requirements

| Location Type | Minimum IP Rating | Additional Requirements |

|---|---|---|

| Indoor mechanical rooms | IP54 | Standard protection |

| Rooftop installations | IP65 | UV-resistant housing |

| Coastal properties (<1 mile) | IP67 | 316L stainless, conformal coating |

| Outdoor equipment pads | IP65-67 | Weatherproof conduit connections |

| Pool/spa equipment rooms | IP67-68 | Chemical-resistant materials |

4. Electrical Requirements and Certifications

Florida building codes and insurance requirements often mandate specific certifications:

- UL 508 – Industrial control equipment standard compliance

- CSA C22.2 – Canadian Standards Association approval for cross-border projects

- ATEX/IECEx – Explosion-proof certification for hazardous locations

- Voltage ratings – Match to 24VAC, 120VAC, or 240VAC control circuits

SUCO ESI North America Product Recommendations by Application

For Residential and Light Commercial (<25 Tons)

- Model 0169 Series: Mechanical pressure switches, adjustable setpoints, UL/CSA listed

- Pressure ranges: 0-150 PSI (low), 0-500 PSI (high)

- Electrical: 15A @ 250VAC switching capacity

- Benefits: Cost-effective, proven reliability, simple installation

For Commercial Buildings (25-500 Tons)

For Commercial Buildings (25-500 Tons)

- GS4000 Series: Electronic pressure transmitters with 4-20mA output

- Accuracy: ±0.25% full scale for BAS integration

- Features: Dual setpoint alarms, display option, MODBUS communication

- Benefits: Building automation compatibility, diagnostic feedback

For Industrial and Critical Facilities

- HI2000 Series: High-precision SoS sensors, ATEX certified

- Performance: <0.2% long-term stability, -40°F to 200°F operation

- Approvals: ATEX, IECEx, SIL 2 functional safety

- Benefits: Extreme reliability, hazardous area approval, predictive maintenance capability

🏗️ Critical HVAC Applications Requiring Reliable Pressure Switches

Mechanical and electronic switches for AC and HVAC systems protect millions of dollars in equipment while ensuring occupant comfort across diverse Florida applications.

Commercial Building HVAC Systems

High-Rise Office Buildings

Miami’s skyline, Tampa’s downtown towers, and Orlando’s corporate centers depend on sophisticated HVAC systems where pressure monitoring is mission-critical:

- Chilled water systems (150-300 PSI operating pressures)

- Condenser water loops requiring differential pressure monitoring

- Variable refrigerant flow (VRF) systems with multiple pressure zones

- Building automation integration demanding reliable electronic signal output

Retail and Hospitality

Florida’s $112 billion tourism industry relies on climate-controlled comfort in hotels, restaurants, and shopping centers where HVAC failure means lost revenue:

- Rooftop packaged units requiring high/low pressure cutouts

- Walk-in coolers and freezers with critical safety pressure switches

- Kitchen ventilation systems monitoring static pressure

- Multiple zone control utilizing electronic pressure switches

Industrial and Manufacturing Facilities

Food Processing and Cold Storage

Florida’s $137 billion agriculture industry depends on precise climate control:

- Ammonia refrigeration systems requiring explosion-proof ATEX-certified switches

- Cold storage warehouses maintaining -20°F to 35°F temperatures

- Process cooling applications with corrosive refrigerant exposure

- FDA compliance requirements demanding documented calibration and reliability

Pharmaceutical and Healthcare

Miami’s growing life sciences sector and Florida’s extensive healthcare infrastructure require:

- Clean room environmental control with ±0.1°F temperature stability

- Laboratory HVAC systems maintaining precise negative/positive pressures

- Medical gas monitoring where failure isn’t an option

- ISO 13485 compliance for medical device manufacturing facilities according to ISO standards

Residential and Multi-Family Applications

Condominium and Apartment Complexes

Florida’s 3+ million multi-family housing units create enormous HVAC equipment demands:

- Central chiller plants serving hundreds of units

- Individual split systems requiring reliable high/low pressure protection

- Pool equipment rooms with high humidity and chlorine exposure

🌎 SUCO Service Excellence

While SUCO ESI North America maintains a strong presence serving Florida from our Deerfield Beach, FL facility, our comprehensive network ensures coast-to-coast support across Canada, the USA, and latin america.

Comprehensive USA Coverage

From our St. Louis, MO headquarters and Florida facility:

- Technical support

- Custom solution development for unique HVAC applications

Canadian Market Expertise

- CSA certification on all relevant products for Canadian code compliance

- Bilingual documentation (English/French) supporting Quebec operations

- Cold-climate expertise for applications requiring -40°F performance

- Cross-border logistics ensuring smooth customs and duty handling

Mexico Manufacturing Support

Supporting Mexico’s growing industrial and manufacturing sectors:

- Spanish language technical support and documentation

- NAFTA/USMCA compliant products and logistics

- Hazardous area certifications for petrochemical and industrial facilities

- Local distributor network in major manufacturing regions

Request a Quote Today!

Ready to get precise, high-performance pressure measurement solutions for your industrial applications?

Email Us: sales@sucoesi.com

Installation Best Practices for HVAC Environments

Proper installation of mechanical and electronic switches for AC and HVAC systems prevents 80% of field failures and ensures optimal performance.

Location and Mounting Considerations

Refrigerant Line Installations

- Mount switches in accessible locations for future service

- Install upstream of expansion devices on high-pressure side

- Use vibration dampening on compressor discharge lines

- Ensure proper orientation per manufacturer specifications (typically upright)

Environmental Protection

- Route electrical conduit with drip legs preventing water entry

- Apply dielectric grease to all electrical connections

- Use UV-resistant cable ties and protective sleeving

- Install sunshades on electronic switches exposed to direct Florida sun

Electrical Connections and Integration

Safety-Critical Wiring

Pressure switches protecting compressors should be wired in series with safety chain:

- High-pressure cutout (opens at 550-600 PSI for R-410A residential)

- Low-pressure cutout (opens at 25-50 PSI)

- Thermal overload protection

- Emergency stop circuit

Building Automation Integration

Electronic pressure transmitters require proper signal conditioning:

- 4-20mA loops: Use shielded twisted pair, maximum 500-1,000 ft runs

- 0-10V signals: Separate from power wiring, maximum 300 ft recommended

- Digital protocols: Follow MODBUS/BACnet network installation standards per ISA guidelines

- Grounding: Establish single-point grounds preventing ground loops

💰Why Quality Pressure Switches Pay for Themselves

Investing in reliable mechanical and electronic switches for AC and HVAC systems delivers measurable financial returns through multiple channels.

- Direct Cost Savings

- Reduced Emergency Service Calls

Extended Equipment Life

Reliable pressure monitoring prevents catastrophic failures:

- Compressor replacement cost: $2,500-$15,000 depending on size

- Average compressor life: 12-15 years with proper protection vs. 8-10 years without

- Commercial chiller replacement: $100,000-$500,000+ for large facilities

Operational Efficiency Gains

Energy Savings Through Optimal Performance

Accurate pressure monitoring enables precision system tuning:

- Maintaining optimal subcooling/superheat reduces energy consumption 5-15%

- A 100-ton commercial chiller at $0.12/kWh saves $3,600-$10,800 annually

- Electronic pressure monitoring enables predictive maintenance, preventing degraded efficiency

🔍 Troubleshooting Common Pressure Switch Issues in HVAC Systems

Understanding common failure modes helps maintain reliable operation of mechanical and electronic switches for AC and HVAC systems.

Mechanical Switch Failures

Symptom: Nuisance tripping (switch opens without actual pressure problem)

- Pressure spikes from liquid slugging → Install inline snubber/damper

- Vibration causing contact chatter → Add vibration isolation mounting

- Corrosion on contacts → Replace with higher-grade contact material (gold-plated)

- Setpoint drift from spring fatigue → Recalibrate or replace (typical 10-year service life)

Symptom: Switch fails to open at pressure setpoint

- Diaphragm damage from pressure overshoot → Install overpressure protection, replace switch

- Contact welding from high inductive loads → Add relay with proper coil suppression

- Internal corrosion → Use switches with proper environmental rating for application

Electronic Switch Troubleshooting

Symptom: Erratic 4-20mA signal output

Diagnostic Procedure:

- Verify power supply voltage (typically 12-36VDC)

- Check loop resistance (<500Ω for most transmitters)

- Inspect wiring for damaged insulation or moisture intrusion

- Test transmitter with precision resistor load

- Verify proper grounding preventing EMI interference

Symptom: Reading doesn’t match gauge pressure

Possible Causes:

- Zero/span adjustment needed (annual calibration recommended)

- Temperature compensation error (verify operating within rated range)

- Sensor drift (SoS sensors show <0.2% over 10 years, verify with calibration equipment)

📋 Frequently Asked Questions

Q: How often should HVAC pressure switches be replaced in Florida’s harsh environment?

A: Mechanical pressure switches in coastal or outdoor installations typically require replacement every 8-12 years due to environmental exposure. Inland installations may achieve 12-15+ year service life. Electronic pressure switches using Silicon-on-Sapphire technology can exceed 15-20 years with proper installation and minimal drift, though periodic calibration (every 2-3 years) ensures continued accuracy for critical applications.

Q: What’s the difference between a pressure switch and a pressure transducer?

A: A pressure switch provides simple on/off output at specific setpoints—ideal for safety cutouts and basic control. A pressure transducer (or transmitter) provides continuous analog or digital signal output proportional to pressure, enabling precise monitoring, data logging, and building automation integration. Modern HVAC systems often use both: switches for safety functions, transducers for optimization and monitoring.

Q: Can I use the same pressure switch for different refrigerants?

A: Generally yes for common refrigerants (R-22, R-410A, R-134a, R-404A) as they have compatible pressure ranges. However, newer low-GWP refrigerants (R-32, R-454B, R-1234yf) may require verification of elastomer compatibility. Ammonia (R-717) and CO2 (R-744) applications absolutely require specifically rated switches. Always consult manufacturer specifications before substituting refrigerants.

Q: Do electronic pressure switches require special programming for HVAC applications?

A: Basic electronic switches with fixed setpoints require no programming—simply wire the alarm outputs. Advanced transmitters with field-programmable setpoints typically use DIP switches or button sequences (no software required). Building automation integration via MODBUS/BACnet requires configuration but follows standard protocols that most BAS contractors handle routinely.

Q: Why choose SUCO ESI North America over cheaper alternatives from online suppliers?

A: The initial cost difference ($50-$150) becomes insignificant compared to failure costs ($2,500+ compressor replacement, $5,000+ daily downtime). SUCO ESI provides: (1) 80+ years proven German engineering, (2) Silicon-on-Sapphire technology with superior long-term stability, (3) comprehensive North American technical support, (4) proper certifications (UL, CSA, ATEX), and (5) full warranty backing. Additionally, counterfeit pressure switches from unauthorized sources create liability exposure for contractors and facility owners.

Q: How does SUCO ESI support customers across Canada, the USA, and Mexico?

A: Our dual-facility structure (St. Louis, MO and Deerfield Beach, FL) combined with an extensive distributor network provides: 2-3 day standard delivery throughout North America, local technical representatives in major markets, bilingual support (English/Spanish/French), cross-border logistics expertise, and product certifications meeting USA (UL), Canadian (CSA), and international (IECEx) requirements. We maintain inventory to support both routine and emergency needs across all three countries.

Partner with Pressure Measurement Experts

When Florida’s demanding climate, diverse applications, and critical operational requirements intersect, you need mechanical and electronic switches for AC and HVAC systems engineered for extreme reliability. SUCO ESI North America brings Silicon-on-Sapphire technology, comprehensive certifications, and 80+ years of pressure measurement expertise to every application—from Miami Beach condominiums to Orlando theme parks, from Tampa industrial facilities to Jacksonville commercial towers.

Why HVAC Contractors and Facility Managers Choose SUCO ESI North America

- ✅ German Engineering Excellence – Precision manufacturing meeting the highest quality standards

- ✅ Florida-Specific Expertise – Understanding coastal corrosion, extreme heat, high humidity challenges

- ✅ Comprehensive Product Range – Mechanical and electronic solutions for every HVAC application

- ✅ Technical Support – Real engineers, not scripted call centers

- ✅ Fast Delivery – Local inventory and distribution centers ensure rapid fulfillment

- ✅ Long-Term Reliability – Silicon-on-Sapphire sensors with <0.2% ten-year drift

Request a Quote Today!

Ready to get precise, high-performance pressure measurement solutions for your industrial applications?

Email Us: sales@sucoesi.com

Whether you’re specifying pressure switches for a new construction project, upgrading aging HVAC equipment, or seeking reliable solutions for critical facilities, SUCO ESI delivers the performance, support, and value that keeps North American buildings comfortable and efficient.

Don’t let inferior pressure switches compromise your HVAC system’s reliability. Contact SUCO ESI today for expert product selection assistance, technical specifications, and competitive pricing on mechanical and electronic switches for AC and HVAC systems engineered to excel in Florida’s demanding environment—and throughout Canada, the USA, and Latin America. 🌟