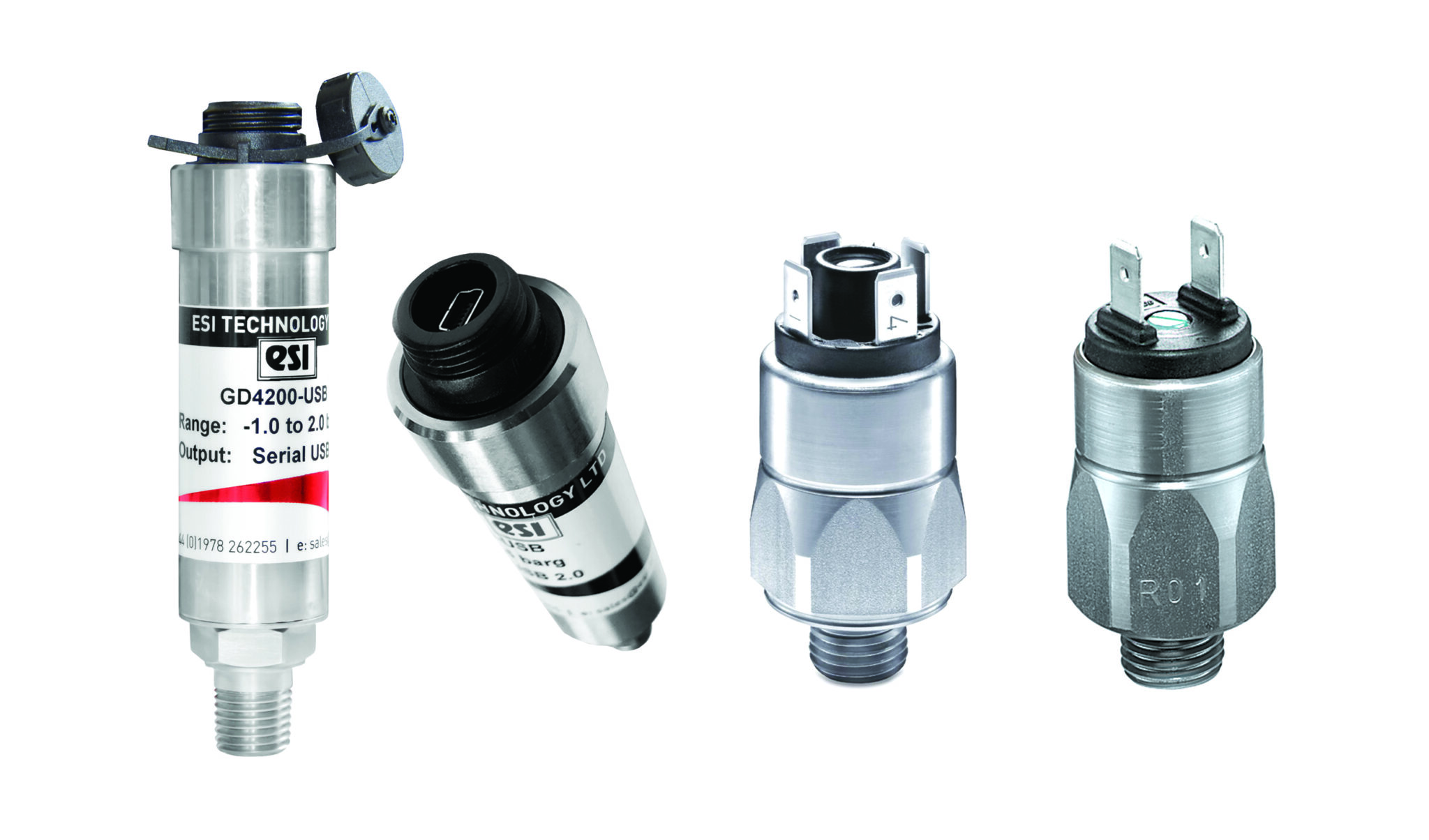

Safety plays a key role wherever systems in medical applications operate under pressure. Our mechanical and electronic pressure and vacuum switches as well as transmitters measure pressure accurately and reliably in medical systems. All products are 100 % tested before they leave our production facility. Using SUCO products ensures the reliability of your system.

SUCO Pressure Switches are used to:

- Medical Ventilators and Respirators

- Monitoring of Gas Supply in Anesthesia Systems

- Control of Medias in Sterilization and Cleaning-Units

- Control of Hydraulic Supply in Operating Tables

- Control Incoming Pressure for Ozone Analyzers (Hyperbaric Ozone Therapy) switching the Machine off upon reaching the specified level or if Safety Sensor fails

- Monitoring of Incoming Pressure of Medical Oxygen before mixing with Ozone in Ozone Generators

- Indicate interferences in Gas Pipe Systems of Medical Gas Supply Systems

- Control the Bottle Pressure of Anesthesia Systems, and the Hydraulic Lift Control of the Operating Table

Ventilator equipment is a generic term for a large number of different designs, including mobile devices for the emergency services or home ventilation equipment. In intensive care units, ventilators are used to ventilate patients for longer periods. The ventilators used to treat COVID-19 belong to the class of anesthesia and intensive care ventilators. Ventilation is performed with a mixture of oxygen and compressed air to which an anesthetic is added if necessary. Our pressure switches monitors the supply of oxygen in the ventilator, and respirator control valve. Click here for product info.

Ventilator equipment is a generic term for a large number of different designs, including mobile devices for the emergency services or home ventilation equipment. In intensive care units, ventilators are used to ventilate patients for longer periods. The ventilators used to treat COVID-19 belong to the class of anesthesia and intensive care ventilators. Ventilation is performed with a mixture of oxygen and compressed air to which an anesthetic is added if necessary. Our pressure switches monitors the supply of oxygen in the ventilator, and respirator control valve. Click here for product info.

Disinfection and cleaning systems as a given standard in hospitals and medical practices are being produced in very large quantities. The machines initially look very similar to dishwashers, but are used to clean and disinfect instruments and medical devices. The machines work at high temperatures and have the possibility to use disinfectants and special cleaning liquids to (safely) remove both mechanical and biological soiling on the instruments.

Autoclaves and sterilizers kill all pathogens capable of reproduction using hot steam under high pressure switches. In order to withstand the high pressures, the chambers are normally built in a barrel shape. Normally, autoclaves sterilize at 134°C with a holding time of 5.5 minutes. The systems are first evacuated and then filled with hot steam. These units sterilize instruments contaminated with viruses in combination with upstream cleaning systems. SUCO ESI North America has been supplying these customers for many years in two main application areas:

- Water ring pumps evacuate the chambers. The pressure switch monitors the water supply to the pumps.

- Door lock – An additional pressure switch monitors the interior and prevents opening of the devices during sterilization.

Hydraulic systems are used, for example, in operating tables or rescue tables to safely lift the patient in all positions But also large systems mounted on rollers can be locked and secured with hydraulic rams. See Mechanical pressure switch for hydraulic systems. In hospitals, gas and media supply is normally ensured by permanently installed supply lines. Our pressure switches and pressure transducers monitor the cylinder pressures in the central gas supply as well as the supply for different systems in the treatment room. Our pressure switches are suitable for oxygen (O2) and also for high pressures. Due to the flammability of oxygen, these products are subject to special restrictions in terms of material selection and country-specific approvals or handling regulations. SUCO offers pressure switches approved and tested for oxygen up to 2,900 psi (200 bar). One application is monitoring oxygen supply in ozone therapy. The ozone (O3) is extracted directly from oxygen on site.

Approved Materials and Certifications

SUCO ESI North America, offers numerous products with materials suitable for medical technology. Due to the high temperature and corrosion resistance, pressure switches are often made of stainless steel or brass, especially for monitoring drinking water or media containing water, and it is a standard in many medical technology products. For oxygen and water applications SUCO recommends the use of EPDM diaphragms:

- EPDM diaphragm for general applications (including oxygen). The burnout safety was tested by the Federal Institute for Materials Research and Testing (BAM). In addition to EPDM, the following diaphragms are mainly used in medical applications.

- The FKM diaphragm has been successfully tested for bio-compatibility (luminescent bacteria test) as part of the evaluation for ventilators.

- The Silicone diaphragm has a US FDA (Food & Drug Administration) approval for food and pharmaceutical applications. See Diaphragm Pressure Switches

Let us offer the pressure switch or pressure transducer that best fits your application.

Contact us > Phone: 1-800-473-7313 | Email: sales@sucoesi.com